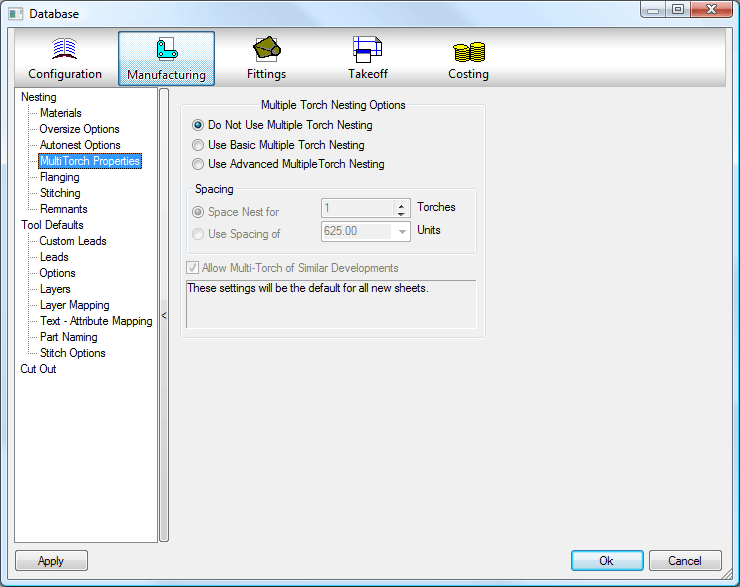

The MultiTorch Properties section of the database lets you configure multiple tools on the same beam. This is not to be confused with multiple tool heads, on which the beam has a single torch but multiple heads. The MultiTorch Properties options are for machines that simultaneously cut more than one part by having torches that share the same NC data.

- Open the Installed Machines Database.

- Select the required machine, click Tools and highlight the tool.

- Click Setup and then Add.

- Click on number of heads from the drop-down box and then OK.

- To alter the number of heads, click on number of heads and edit the amount.

Do not Use Multiple Torch Nesting: Selecting this option cancels the multi-torch nesting.

Use Basic Multiple Torch Nesting: Enables basic multi-torch nesting settings.

Use Advanced Multiple Torch Nesting: Enables the Advanced Multi-Torch nesting settings.

Space Nest for - Torches: Allows for a number of torch heads to be specified and then the largest part size is used as the spacing. The amount of spacing required can be printed on nest reports as "Sheet M-Torch Spacing".

Use Spacing of - Units: Allows for a fixed spacing value to be specified between torches. This value will delimit the size of the parts that can be successfully placed on to the sheet.

Allow Multi-Torch of Similar Developments: This allows similar developments belonging to different items to be linked together for nesting. For example, if this is used with a machine with two torches, and two radius bends are entered into a job with the same top and bottom panels but different throats and back wrappers, the top and bottom panels from both bends could be treated as the same part for nesting, and they could be cut at the same time, one part by each torch.