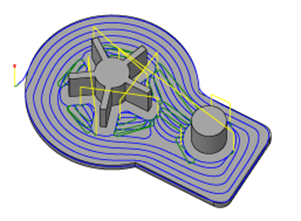

2D Adaptive Clearing milling strategy

2D Adaptive Clearing is a roughing toolpath that avoids abrupt direction changes.

You can clear a cavity, open pocket, or the area around a boss by selecting edges, sketches, or solid faces as the machining area.

Adaptive toolpath around two circular boss features.

Sudden changes in how much of the tool is engaged while cutting material around it can cause tool breakage. To avoid sudden changes in tool engagement, 2D Adaptive Clearing maintains a constant engagement between the tool and its surrounding material. The Optimal Load parameter sets the level of engagement and can be adjusted depending on the tool manufacturer's recommendations.

The 2D Adaptive Clearing toolpath is preferred for roughing simple pockets and other simple geometry whereas 3D Adaptive Clearing offers more control and can be used for more complex geometry.