Generate a Bore toolpath

On the Manufacture workspace toolbar, click Milling > 2D > Bore.

The Bore dialog opens.

On the Tool tab, click Select to pick a tool. If you have not created a tool to use, in the left panel of the dialog, from the Fusion Library, pick a tool from the Sample Tools library.

Tip: Bull-nosed and flat end mills are best suited for removing material with a toolpath like Bore.

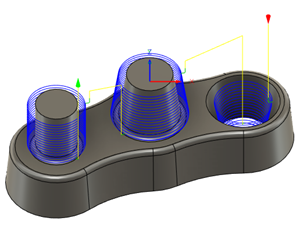

On the Geometry tab, from the Selection Mode drop-down menu, select Faces.

With the Circular Face Selections field active, select cylindrical or conical faces on the model that you want to machine. The toolpath preview appears as you select each face.

Tip: Mouse over the Circular Face Selection box for more information.

On the Passes tab, adjust the Pitch parameter to specify the distance to feed down for each 360-degree revolution the tool performs around the geometry. For straight walls, this value is generally larger than for tapered walls.

Set the Compensation Type to specify how to adjust for any tool wear.

Tip: Mouse over the Compensation Type parameter drop-down list for more information.Optional steps:

To use a Ramp Angle instead of a Pitch value to specify the feed depth, enable the Use Ramp Angle checkbox.

To generate multiple side cuts, enable the Multiple Passes checkbox.

To finish a wall when roughing and finishing with the same tool, enable the Finishing Pass checkbox.

To clear any stock that is left over from tool deflection, enable Repeat Passes to repeat the pass. The repeating pass is commonly referred to as a spring pass.

For safer entry and exit moves on smaller holes, on the Linking tab, in the Leads & Transitions group, enable the Lead to Center checkbox.

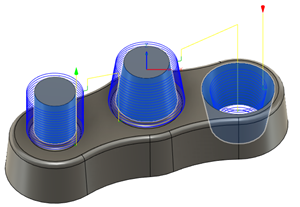

Click OK.

The toolpath is generated.