Choice of passes for the Corner toolpath

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

You have the choice of three types of toolpaths when generating a Corner toolpath:

- Along with maximum stepover

- Along with constant stepover

- Across

Along

When using the Along type, passes run along the material, for example along an internal corner, and is generally used to machine the shallow areas on a part.

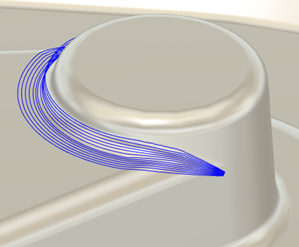

When using Along with maximum stepover, the stepover adjusts itself to always remain within the stock boundary, so that the surface finish of the surrounding area is not affected. The maximum stepover occurs at the widest part of the stock boundary. If the stock boundary narrows down, the stepovers move closer together, leaving less material to cut on each stepover and potentially cause the tool to rub on the part.

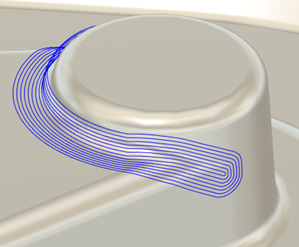

When using Along with constant stepover, a constant stepover is maintained throughout the stock boundary so that you get a constant chip thickness, resulting in better cutting conditions. If the stock boundary narrows down, the outermost passes may encroach the surrounding area that is already machined, potentially causing marks to the surface finish.

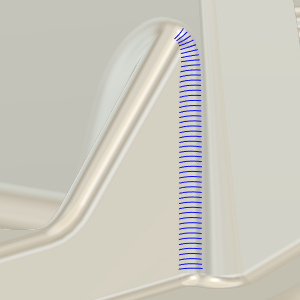

In the example below, you see a stock boundary at the bottom of a circular boss and the result of using Along with maximum stepover and the constant stepover.

|

|

|

|

| Along with maximum stepover | Along with constant stepover |

Across

Passes run across the material, for example across an internal corner, and is generally used for machining steep areas.

Using Across for vertical walls helps prevent running the tool vertically down the corner, which can increase the chance of tool breakage.