Activity 1: Create the setup

In this activity, start by creating a Setup.

Normally a machining operation is started by creating a Setup. A setup defines a number of general properties for a set of machining operations - including the Work Coordinate System (WCS), the stock geometry, fixtures, and the machining surfaces. If you do not create a setup manually before adding your first operation, a setup with default parameters is created for you automatically.

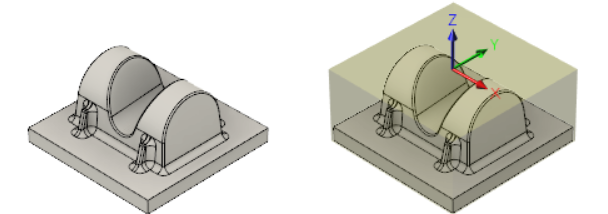

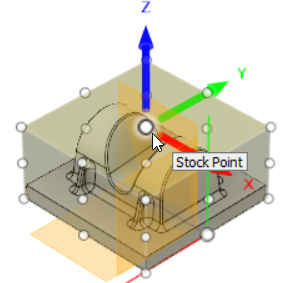

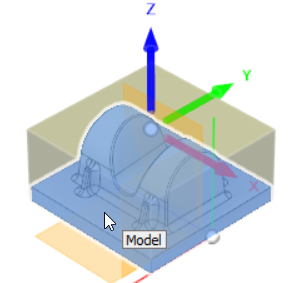

No Setup present (left). Setup created (right).

Steps

Set the Work Coordinate System (WCS) by defining the XYZ orientation and the location of the Origin.

- On the Manufacture toolbar, Milling tab, select Setup > New Setup

to display the Setup dialog. Note: On the canvas, the stock material is created automatically around the bounding box of the part.

to display the Setup dialog. Note: On the canvas, the stock material is created automatically around the bounding box of the part. - In the Work Coordinate System (WCS) group, choose Select Z Axis/Plane & X Axis from the Orientation drop-down menu.

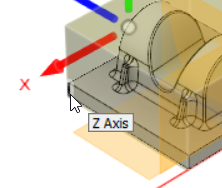

- Make sure the Z Axis button is active and select the vertical edge at the lower left of the part as shown in the following image:

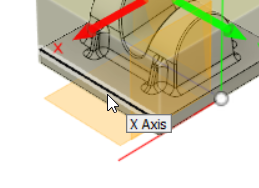

- The Z axis is now oriented correctly, but the X axis must be redefined. Make sure the X Axis button is active and select the horizontal edge on the part base as shown below:

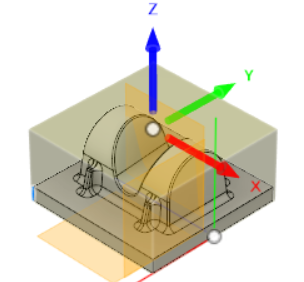

- The direction of the X axis may need to be flipped. If it does, activate the Flip X Axis checkbox so that the WCS triad matches that shown in the following image:

- The orientation of the new WCS is now correct. Now, the origin must be redefined. choose Stock box point from the Origin drop-down menu.

- Click the Stock Point button and select the point (represented by a white dot) at the top center of the stock as shown in the following image:

- On the Manufacture toolbar, Milling tab, select Setup > New Setup

Define the model surfaces. Note: As with the stock, defining the machining surfaces is not strictly necessary. But we do it here as an exercise for more complicated setups.

- In the Model group, click the Model button.

- Click the model within the stock to select the part as the machining surfaces as shown in the following image:

- Click OK to exit the Setup.

Activity 1 summary

In this activity, you created a Setup. You did this by defining the location of your Workspace Origin and the XYZ orientation. You also specified the model surfaces to be machined. The Stock box was created automatically, and we used its default settings.