Machine Thin Walls reference

Fusion includes special support for machining thin walls with the Contour Finishing strategy.

On a part with thin walls, running the contour finishing with default settings creates a toolpath ordered by area. In the case of a thin walled pocket, this can cause the wall to break when machining one side completely before the other side.

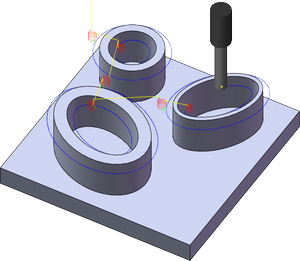

The problem can be avoided by enabling the Order by Depth option on the Passes tab, which finishes an entire Z-level before moving to the next.

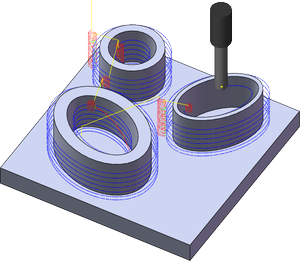

Order by area (default)

Order by Depth

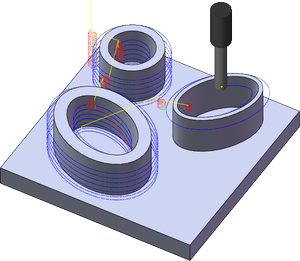

In parts with both thin walls and thicker walls, ordering by depth can unfortunately cause some extra linking. In CAM, however, you can enable the Use Thin Wall option instead which allows you to control when the toolpath should be ordered by depth instead of by area.

For example, there are three upstands with walls of 2 mm, 4 mm and 6 mm thicknesses on the part shown above. If you set the Thin Wall Width to 3 mm, the toolpath on the upstand with 2 mm walls is machined by depth, while the other two upstands are machined by area.

Using thin wall with a thin wall width of 3 mm