Build volume optimization for additive manufacturing

The Fill Build Volume ![]() tool lets you fill the unused space in an additive machine’s build volume with multiple copies of a component. The copies of the component are stored as new components within the active Manufacturing Model.

tool lets you fill the unused space in an additive machine’s build volume with multiple copies of a component. The copies of the component are stored as new components within the active Manufacturing Model.

Filling the build volume can be useful when printing batches of identical parts or including additional parts around a main part. This can help maximize production capacity.

2D and 3D filling types

While the arrangement of component copies within the build volume happens automatically, you can use the Filling Type and its advanced settings to control the way the use of space is optimized.

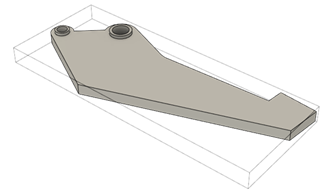

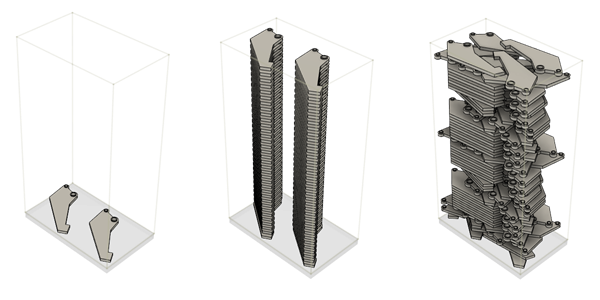

When you choose the 2D Fill (Bounding Box) filling type, all copies of the component are distributed in a single layer on the surface of the platform. This can be useful if you do not want the copies to be stacked on top of each other. If you want the copies to be distributed within the entire volume of the build instead, select one of the 3D filling types.

The difference between the two 3D filling type options lies in how the optimal use of space is approximated and in the accuracy of the computation.

3D Fill (Bounding Box) offers a faster, simplified approach: Fusion takes the bounding box of the component as an approximation of the component's shape to determine how much space is needed for each copy. All the copies keep the same orientation in the 3D space as the original component.

3D Fill (True Shape) uses the actual shape of the component in the computation to provide a more compact 3D arrangement. In addition, this option lets you specify whether copies can be rotated within the build to optimize the use of space.

In both 3D filling types, the space within the build is divided into 3D units called voxels. By default, during the arrangement computation, Fusion fills the space of the build with component copies up to a point where no more copies could fit within the remaining empty voxel groups. You can control the level of precision of the computation by specifying a custom voxel size. The lower the voxel size, the more precise the computation.

If you want to limit the number of copies produced to a specified number, select the Limit Number of Copies checkbox.

Example of components filling a build volume in 2D Fill (Bounding Box) (left), 3D Fill (Bounding Box) (center), and 3D Fill (True Shape) with the Rotations checkbox selected and X, Y, and Z rotations set to Custom: 20 degrees (right).