Add an Edge with Bar Support structure

Ensure that you have an additive setup with an SLA/DLP or MPBF additive machine selected.

On the Manufacture workspace toolbar, click Additive > Supports > Edge with Bar Support

.

.The Edge with Bar Support dialog opens.

With Selection active, on the canvas, click the solid bodies, the faces of solid bodies, or the mesh face groups that you want supported.

Tip: To prevent supports generating at certain areas, select the Avoid checkbox, ensure Avoided Model is active, and then, on the canvas, click the solid bodies, the faces of solid bodies, or the mesh face groups.In the General tab, enter a Maximum Angle to XY-Plane to specify the angle of edges, below which supports get added.

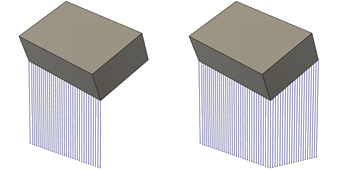

Example of a Maximum Angle to XY-Plane of 20 degrees (left) and 35 degrees (right).

Enter a Bar Distance to specify the maximum distance between individual bar supports.

Enter a Minimum Z Value and a Maximum Z Value to specify the smallest and highest heights, between which supports get added.

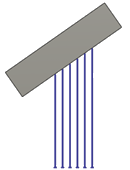

Example of bar supports with a Minimum Z Value of 30 mm and a Maximum Z Value of 40 mm.

In the Bar Properties tab, choose options for Bar Size and Bar Shape to specify how thick the supports are and determine the cross-sectional shape of the supports.

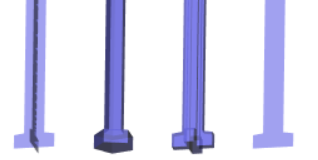

Example of Cross (left), Solid Bar and Single Hatch Tube (center left), Solid Cross (center right), and Hatch (right) bar shapes. A Single Hatch Tube is the same shape as a Solid Bar, but the way the Single Hatch Tube is sliced during export is different.

Optional steps:

To ensure that bar supports terminate in a right angle at the supported surface, in the Bar Properties tab, select the Right Angle on Part checkbox.

To create support-to-part connections that make the supports easy to break off by hand, in the Connections tab, select the Breakpoint checkbox and choose the Breakpoint Type.

To prevent a thickening of the supports at the build platform, in the Connections tab, deselect the Pad on Platform checkbox.

Click OK.

The supports are generated and, in the Browser, under the Supports node, an Edge with Bar Support child item is added.

Tip: To reuse these support settings in the future, right-click the child item and choose Store as Template to add it to the Template Library.

If the setup uses an MPBF or eBeam additive machine, you can now generate, and then simulate, the additive toolpath. Otherwise, export the build file.