Advanced Swarf milling strategy

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

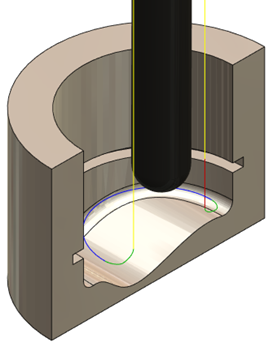

Advanced Swarf, also called flank milling, is a multi-axis strategy to machine straight-sided walls with the side of the tool. It aims to machine the walls with one or more cuts using the whole flute length of the tool.

Using this strategy, you can achieve a higher quality of surface finish and faster finishing cycles.

A common use of this strategy is to machine parts with pockets or bosses that have a positive, negative, or variable draft angle, like parts for the aerospace industry.

The Advanced Swarf toolpath with one pass using the full length of the cutter.

Comparing Advanced Swarf and Swarf strategies

The Advanced Swarf strategy is similar to Swarf, but it offers the following benefits:

- Flexibility in defining toolpath geometry.

- Accurate control of the tool axis through flexible synchronization between the Upper and Lower Guide Curves. You can also automatically synchronize these curves.

- A capability to create 3-axis, 4-axis, and 5-axis toolpaths depending on your part geometry and capabilities of your machine.

Advanced Swarf Geometry

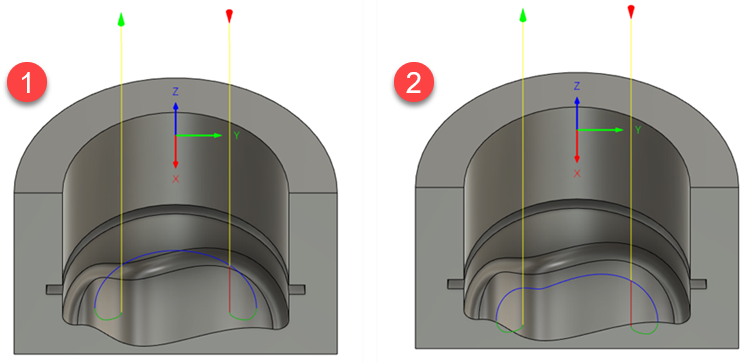

The Advanced Swarf strategy requires an upper and lower curve of the geometry to machine. The curves guide the tool to generate the toolpath.

You can select the curves, called Guide curves, on the canvas. Alternatively, you can select surfaces that the strategy uses to define the curves.

The recommended option is to select Surfaces. Then, the strategy can determine appropriate tool-axis movements.

Guide Curves for surfaces

If you select surfaces as geometry, you can specify additional Guide curves to have better control over the toolpath. For example, these curves can help you achieve the required tool orientation.

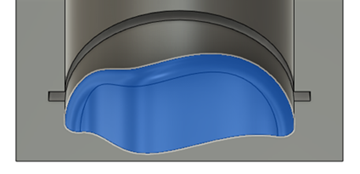

Floor surfaces

You can select floor surfaces of the part so that the tool does not cut through them.

For curved floors, you may want the toolpath to follow the shape of the floor surfaces. To achieve it, select Tool Tracks Floor.