Stepdowns (Rotary Pocket)

Fusion Manufacturing Extension

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

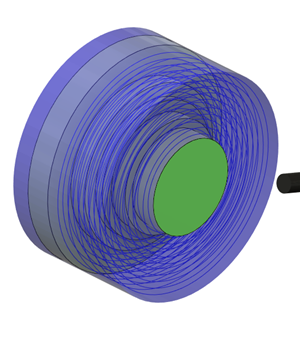

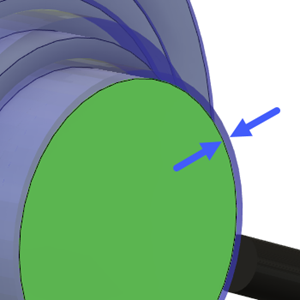

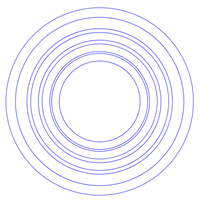

When roughing out a rotary part, you might encounter a scenario where the stepdowns do not coincide with the floor of a part because of the specified Maximum Stepdown value, meaning there is material left over which may require another roughing operation. For example:

|

|

| Rotary part that requires roughing | Stock left over because of stepdown value |

In this scenario, you can change the stepdown value so that the stepdown coincides with the floors, but this may not be desirable as reducing the stepdown by estimation may require multiple attempts at calculating the toolpath, and increasing the stepdown may risk damaging the tool if the cut is too heavy. Instead, you can use:

- Automatic Stepdown — Varies the stepdown between a Maximum Stepdown and Minimum Stepdown value so that the stepdowns coincide with the cylindrical floors. Requires you to enter a Minimum Stepdown.

- Stepdown on Floors — Adds an additional stepdown on cylindrical floors. Where there is already a stepdown coinciding with a cylindrical floor, no extra stepdown is added.

Difference between Automatic Stepdown and Stepdown on Floors

- Generally, on regular cylindrical parts, using Automatic Stepdown will result in fewer stepdowns than using Stepdown on Floors. In this case, Automatic Stepdown may be preferable as fewer stepdowns provides a quicker machining time.

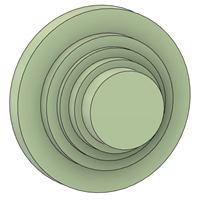

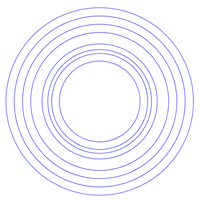

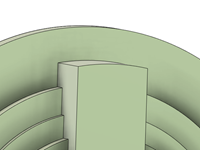

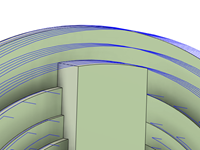

|

|

|

|

| Automatic stepdown | Stepdown on Floors |

| Eight stepdowns | Nine stepdowns |

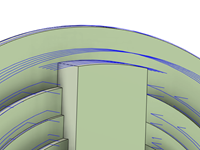

- When machining more complex parts, such as parts with upstands, using Stepdown on Floors may be more efficient. This is because Stepdown on Floors will add a toolpath only over the surface of the upstand. The Automatic Stepdown will adjust an entire stepdown to coincide with a small upstand, which may not be an efficient use of machining time.

|

|

|

|

| Automatic stepdown | Stepdown on Floors |

| Longer machining time | Shorter machining time |