Setup tab (turning or mill/turn) reference

This section covers the parameters that define the stock size, stock shape, WorkCoordinate System (WCS) axis orientation and part zero.

Manufacture toolbar, click Setup > New Setup ![]() .

.

If you are using a Machine Definition, select your machine. Selecting the machine defines the Operation Type.

The information below assumes you have selected a Turning or Mill/Turn , Operation Type.

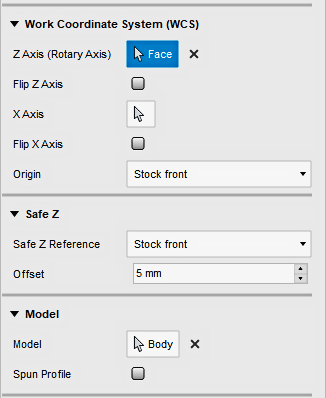

Work Coordinate System (WCS) - Turning or Mill/Turn

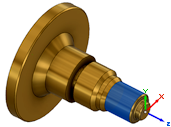

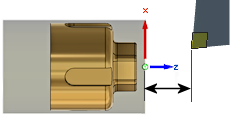

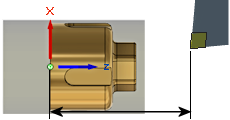

The WCS allows you to set the ZX cutting plane and the Z spindle axis orientation. The Z is almost always on the centerline of the part, and should point away from the chuck/clamping side of the part.

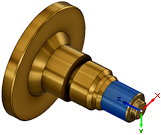

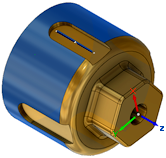

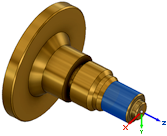

|

|

The WCS options for a turning or mill/turn operation.

- Z Axis (Rotary Axis) - Specifies the axis about which the part rotates. Select a cylinder or sketch line.

- Flip Z Axis - Flips the Z axis 180 degrees.

- X Axis - Specifies the X axis orientation of the part. Select an edge or sketch line.

- Flip X Axis - Flips the X axis 180 degrees.

- Origin - You may choose the Stock front, Stock back, Model front, or Model back as the part origin.

Z Axis (Rotary Axis) Select a cylinder |

Flip Z Axis |

X Axis Sketech line selected |

Flip X Axis |

Origin

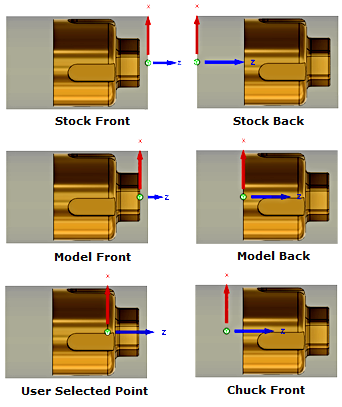

The Origin allows you to set the reference for defining part zero. The drop-down menu offers the following options for locating the WCS origin:

- Stock Front - Allows you to set the reference in relation to the Front of the Stock.

- Stock Back - Allows you to set the reference in relation to the Back of the Stock.

- Model Front - Allows you to set the reference in relation to the Front of the Model.

- Model Back - Allows you to set the reference in relation to the Back of the Model.

- Selected Point - Select a vertex or an edge for the origin reference.

- Chuck Front - Allows you to set the reference in relation to the Chuck position.

Origin Reference Position

Safe Z

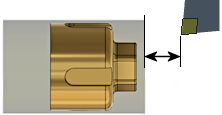

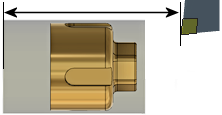

Sets the Z retract position. The Safe Z retract will position at the start or end of a toolpath. The Safe Z Reference position can be from the WCS Origin or the Stock. Set the Offset to provide enough clearance for the tool.

WCS Origin Front Reference and Offset |

WCS Origin Back Reference and Offset |

Stock Front Reference and Offset |

Stock Back Reference and Offset |

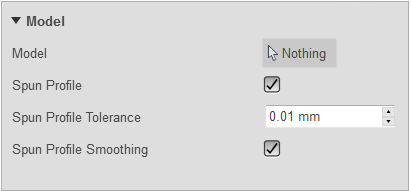

Model

The model defines what is being machined. By default, all the models on the canvas are automatically selected. If you have multiple models representing multiple parts, you can individually select which models you want included in the setup.

Spun Profile

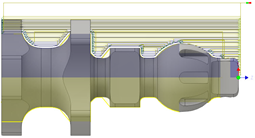

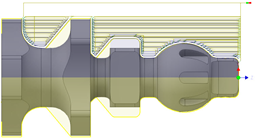

Some turned parts require subsequent milling operations. If your turning part has cross holes, cross slots or undercuts, you can use the Spun Profile option to approximate a 2D profile for 2 axis turning operations.

|

|

| Spun Profile Off | Spun Profile On |

- Spun Profile Tolerance - Specifies the tolerance for the spun profile generation.

- Spun Profile Smoothing - Enable to smooth the profile.

Chuck

Chuck Reference and Offset

You can also specify the reference position and offset distance to the face of the chuck.

|

Select the reference to the chuck face.

|