Reduce Air Cutting option (3D Adaptive Clearing)

Manufacture workspace > Milling > 3D > Adaptive Clearing > Geometry > Rest Machining > Reduce Air Cutting

Air cutting occurs when a tool performs a cutting move but does not engage with any material. This can happen in many different scenarios. A particular scenario where reducing air cutting is most effective is when there is overhanging stock and it is unclear where that stock ends. The result of the overhanging stock is excess cutting moves, in the form of air cutting.

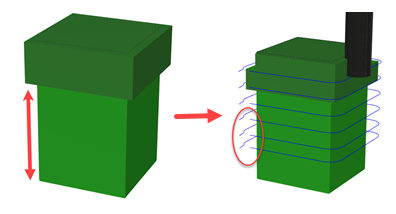

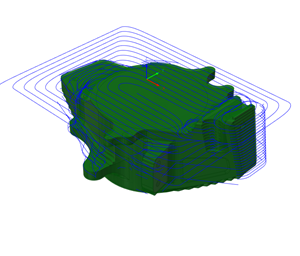

Example of overhanging stock and the resulting toolpath with air cutting:

Turning on Reduce Air Cutting attempts to detect where the stock ends and removes any unnecessary cutting moves, generally resulting in a reduction in machining time.

This feature can add to the calculation time significantly so it is recommended to use it in scenarios where there is a significant reduction in machining time.

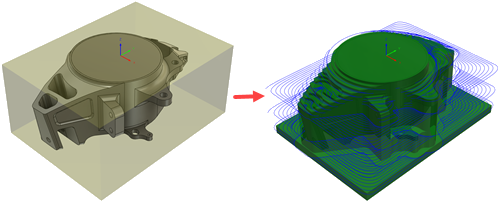

The example below compares the machining time reduction achieved by using Reduce Air Cutting. To begin, a 3D Adaptive Clearing toolpath is generated to machine the top side of the part:

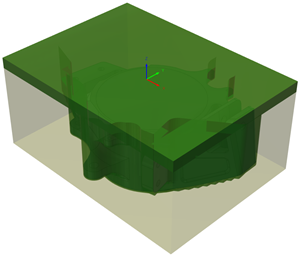

The part is then turned around in a second setup to machine the underside with rest machining:

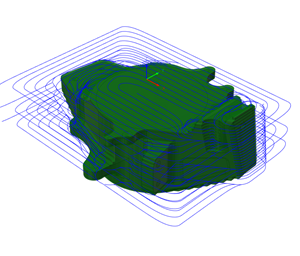

The images below shows the impact of reducing the air cutting moves on the 3D Adaptive Clearing toolpath:

|

|

| Reduce Air Cutting OFF | Reduce Air Cutting ON |

| Excess cutting moves | Efficient cutting moves |

| Machining time = 4:44 | Machining time = 3:20 |