Adaptive Clearing milling strategy

The Adaptive Clearing toolpath is the preferred method for roughing 3D models. It is also effective in 2D prismatic models.

You can clear a 3D boss or cavity using cuts that minimize abrupt changes in direction. This can reduce the possibility of tool breakage and improve tool life.

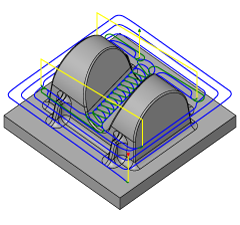

Adaptive toolpath on a 3D boss model.

3D Adaptive Clearing maintains a constant engagement between the tool and its surrounding material. The Optimal Load parameter sets the level of engagement and can be adjusted depending on the tool manufacturer's recommendations. Controls exist for containing the toolpath to a specific area, but as a default, it will assume you want to machine the entire model.

There are 2 methods for creating roughing toolpaths. Adaptive and Pocket. The Pocket strategy takes equal XY step overs and creates climb & conventional toolpath motion. The Adaptive strategy varies the step over and only takes climb cuts.