Turning Adaptive Roughing strategy

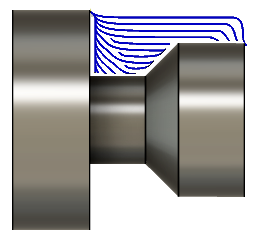

Adaptive Roughing enables you to remove the bulk stock from the part in a series of small, overlapping passes.

The tool removes material following contours of the part which increases efficiency and accuracy of the machining. This strategy is useful for machining complex shapes. It can help reduce machining time, improve surface finish, and increase tool life.

Tools

Adaptive Roughing commonly uses grooving tools, in particular, indexable insert cutting tools, to cut in both directions. Indexable insert cutting tools contain inserts in different shapes and sizes held by a tool holder. You can replace inserts when necessary.

The strategy enables you to specify the amount of material to leave on a part for finishing operations. You can define the Finishing Allowance on the Passes tab, by specifying the radial distance in X and Z axes.

Turning modes

This strategy uses the following modes:

- Outside grooving - machines a groove or channel on the outer surface (outer diameter) of a part.

- Inside Grooving - machines a groove or channel on the inner surface (inner diameter) of a part. Typically uses boring tools to create bores, holes, and other features.

Both modes require selection of appropriate tools.

Groove suppression

To reduce stress on the tool and the part, on the Geometry tab, you can suppress machining grooves in the toolpath. Depending on selected groove faces, Groove Suppression excludes the groove from machining or machines a shallower groove. Large cutting forces may lead to damaging a tool and poor surface finish. By machining a shallower groove, you reduce cutting forces by distributing them on a larger area.