Turning operations

In Fusion, you can create different turning operations and then generate the machine instruction file, for example a G-code file, based on these operations.

To control the shape and size of a part, define a toolpath by specifying the following information.

Tool

Turning tools include a cutter called an insert. Inserts are replaceable and can vary in shape, geometry, material.

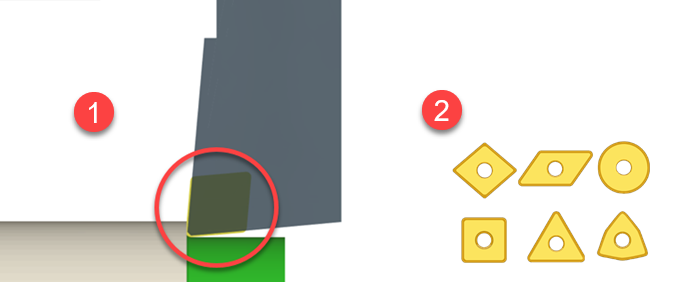

Turning tool removes the stock. The insert is in the red circle. (1) Inserts of different shapes differ in cutting properties. (2)

Select a tool from the Turning Tools library in the Tool Library dialog, or create a tool to use. Make sure that the tool geometry matches the part geometry.

Populate values in the parameter boxes under Feed & Speed depend on a selected preset. Use a default preset or create a preset of your proven feeds and speeds for a specific material, machine, or operation.

Select a tool that is appropriate for the turning mode. The modes vary for operations. A turning mode specifies whether an operation machines the outside diameter, inside diameter, or face of the part.

Toolpath geometry

The toolpath geometry depends on the part geometry and turning operation.

If needed, confine the toolpath axially, in the Z axis, to help the tool maintain a consistent and accurate cutting depth along the length of the part. It also reduces the risk of damaging the tool which may occur when the tool goes too deep in the part. Useful when machining long parts.

For several operations, you can apply Groove Suppression and Rest Machining. If you suppress machining grooves, it reduces stress on the tool and the part. Rest Machining enables you to specify the amount of stock to leave on the part between passes. It can reduce the machining time, tool wear, and energy usage.

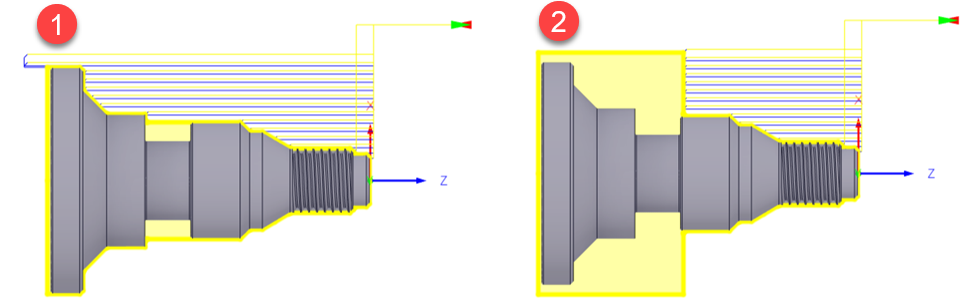

You can extend a toolpath past the model for a longer cut (1) or confine the toolpath within a specific region(2).

Radial confinement of a toolpath

Radial confinement of a toolpath, in the X axis, helps the tool maintain a consistent and accurate position relative to the part diameter. It improves the part quality, but it may increase the machining time. Important when machining parts with varying diameters or with tight tolerances.

Passes

Depending on the operation, select appropriate tool direction, specify multiple passes, stepover, and sharp corners.

If needed, specify the amount of Stock to Leave on the part after completing the operation. The amount depends on the operation and specific part requirements. This parameter helps you achieve the final dimensions of the part after the finishing passes.

Linking

Plan the toolpath to optimize machining efficiency and minimize the risk of collisions with other features of the part.