Casting parameters

| Parameter | Details |

|---|---|

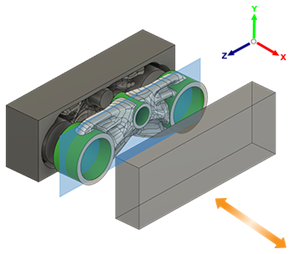

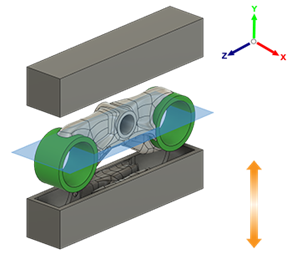

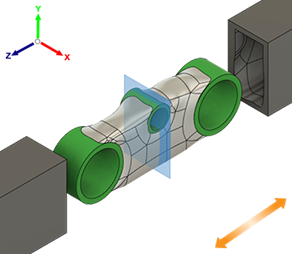

| Ejection Direction | Sets the mold opening directions for the casting operation with reference to the Global Coordinate System.

Note: You can select multiple mold opening directions for a single casting configuration to generate multiple sets of outcomes. |

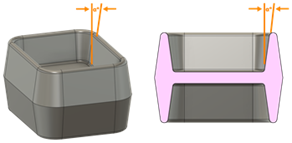

| Minimum Draft Angle | Specifies the angle, or amount of slope, given to walls and other faces to enable easy removal of the part from the mold. All cast surfaces that are parallel to the ejection direction (perpendicular to the parting plane) must be drafted for proper ejection of the part from the mold.  |

| Minimum Thickness | Specifies the expected minimum thickness for the part. Keep the walls as thin as possible to meet the functional requirements. The typical wall thickness depends on factors such as part size, application, configuration, casting process, and materials used. The solver uses the minimum thickness along with other constraints and objectives, such as draft angle, ejection direction, stiffness, safety factor, and target mass. In some cases, the casting outcomes may have areas smaller than the target minimum thickness to meet other constraints. |