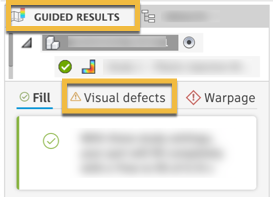

Will my part have visual defects? result

The Will my part have visual defects? result becomes available at the end of the Fill + Pack phase of the analysis, and is located in the Visual defects tab of the Guided Results.

Result interpretation

In the Visual defects tab, the top section of the Guided results interprets the Weld line and Sink marks results and tells you how likely your part is to have these visual defects, based on the conditions specified in the study setup.

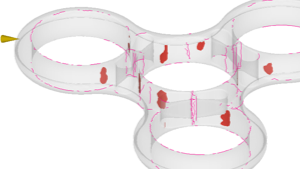

By default, the result interpretation is based on all the part faces. If you have selected aesthetic faces in the study setup, you can filter the information for aesthetic faces only.

The location of these visual defects is shown on the model, and by default both are shown. You can hide one or other using the ![]() Visibility icon in the Next steps section, if you want to focus only on one defect at a time.

Visibility icon in the Next steps section, if you want to focus only on one defect at a time.

Surface Finish

Sometimes, when it is difficult to modify your design, you may have the flexibility to change the surface finish of your part to reduce the appearance of sink marks and weld lines. The Surface Finish command shows you how the visual defects might appear under different conditions of surface texture and reflectivity, to provide you with more alternatives to consider.

Next steps

The bottom half of the guided results panel provides you with options to reduce the appearance or location of the sink marks and weld lines.

In injection molding, changing one parameter may improve one aspect of the injection molding process, such as filling, yet have an adverse effect on another, such as warpage. Within the boundaries of injection molding best practices, therefore, adjusting the parameters is often simply an iterative process.

Tips

- If you plan to modify your model, select the Simulation model option to test out different modifications so you don't alter your original design unnecessarily.

- Consider changing the surface finish to hide visual defects that don't impact the mechanical integrity of the part.