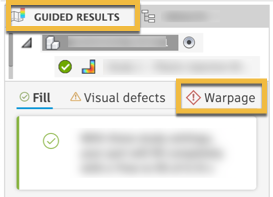

Will my part warp? result

The Will my part warp? result becomes available at the end of the analysis when all the results have been calculated, and is located in the Warpage tab of the Guided Results. All injection molded parts warp - the question is, is the warpage within your design tolerance?

Result interpretation

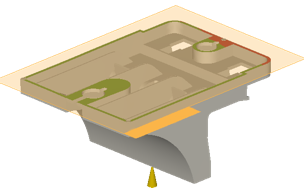

In the Warpage tab, the top section of the Guided results interprets the warpage tolerance result and tells you how much of the part warpage exceeds the tolerance. You can move the tolerance sliders on the legend to alter the tolerance to match your design tolerance. The location of the warpage is shown on your model and updates as you move the sliders.

Flatness

An important aspect of warpage is flatness, which is relevant when a flat surface on one model component needs to adjoin to the flat surface of another component in an assembly, such as in the case of a container with a lid. The Flatness command compares the flat surface that you specify to a flat plane, and tells you what percentage of the surface is out of plane.

The Result interpretation section of the Guided Results updates when you invoke the Flatness command, to inform you of the outcome of the flatness analysis. Use the tolerance slider on the legend to match your design tolerance.

Next steps

The bottom half of the guided results panel provides you with options to reduce the warpage. Each of the recommendations is based on injection molding best practices and the study settings for the specific study.

In injection molding, changing one parameter may improve one aspect of the injection molding process, such as filling, yet have an adverse effect on another, such as warpage. Within the boundaries of injection molding best practices, therefore, adjusting the parameters is often simply an iterative process.

Tip

- Look at the Warpage tolerance result for more information about what warpage is and what factors contribute to warpage.