Activity 2: Reinstate the heatsink on the main regulator and solve

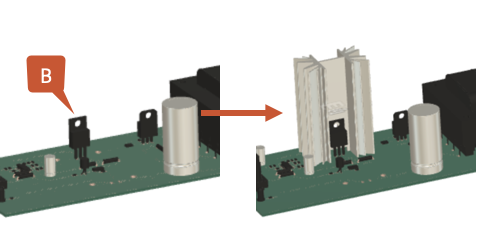

In this activity, you use a heatsink on regulator B to see if the heatsink can reduce the component temperature to below its maximum temperature threshold of 130 C. The heatsink is already modeled, but has been removed.

You

- Clone the original Simulation model and its study setup

- Suppress the removal of the heat sink on regulator B in the cloned Simulation model

- Apply component idealization to the heat sink

- Change the heatsink material to Aluminum 6061

- Solve the study.

Electronics board without a heat sink (left) and with a heat sink on regulator B (right).

Prerequisites

- Activity 1 is complete.

Steps

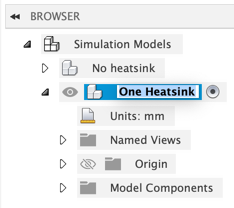

Create a clone of the original Simulation model and its associated study setup, and name it One Heatsink, so you can modify the cloned model without overwriting the results of the original Simulation model.

In the Setup toolbar, select

(Simplify > Simplify) to enter the Simplify environment.

(Simplify > Simplify) to enter the Simplify environment.In the Simplify environment, in the browser, right click the No heatsink Simulation model to open the context menu.

In the context menu, scroll to the bottom and select Clone Simulation Model to open the Clone Simulation Model dialog.

In the Clone Simulation Model dialog, ensure Study 1 - Electronics Cooling is selected, then click OK to create the clone.

In the Browser, double-click the cloned Simulation model to enter edit mode, and rename it One Heatsink.

Reinstate the heatsink associated with regulator B.

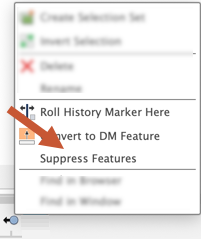

On the Simplify timeline at the bottom of the canvas, right click the last modification, to open the context menu.

In the context menu, scroll down and select Suppress Features to reinstate the regulator B heatsink.

On the Simplify toolbar, click

(Finish Simplify > Finish Simplify) to return to the Setup tab.

(Finish Simplify > Finish Simplify) to return to the Setup tab.

Apply component idealization to the heatsink, to reduce the analysis time while maintaining solution accuracy.

- In the Setup toolbar, select

(Cooling > Heat Sink) to open the Heat Sink dialog.

(Cooling > Heat Sink) to open the Heat Sink dialog. - In the canvas, select the heat sink and confirm that it is highlighted in blue in the canvas and 1 Body is shown in the Heat Sink dialog.

- In the Heat Sink dialog, click OK to accept the change and close the dialog.

- In the Setup toolbar, select

Change the heat sink material to Aluminum 6061.

- In the Setup toolbar, select

(Materials > Study Materials) to open the Study Materials dialog.

(Materials > Study Materials) to open the Study Materials dialog. - In the canvas, select the heat sink and confirm it is highlighted in blue in the canvas and the heatsink row in the Study Materials dialog is highlighted in gray.

- In the Study Materials dialog, in the Study Material column, click the highlighted heatsink row twice to open the list of materials, then select Aluminum 6061 and press Enter on your keyboard.

- Click OK to accept the change and close the dialog.

- In the Setup toolbar, select

Check that the study is setup properly, then run the analysis.

On the Setup toolbar, check

(Solve panel > Pre-check), and confirm it is green with a white check mark.

(Solve panel > Pre-check), and confirm it is green with a white check mark.On the Setup toolbar, click

(Solve panel > Solve), to open the Solve dialog.

(Solve panel > Solve), to open the Solve dialog.In the Solve dialog, click Solve 1 Study to run the analysis and close the dialog.

Note: Meshing and solving the analysis can take several minutes.When the analysis is complete, click Close to close the Job Status dialog.

Activity 2 summary

In this activity, you

- Cloned the original Simulation model and its study setup

- Reinstated the heat sink on regulator B in the cloned Simulation model

- Applied component idealization to the heat sink

- Changed the heatsink material to Aluminum 6061

- Confirmed the study was set up properly, then solved it.