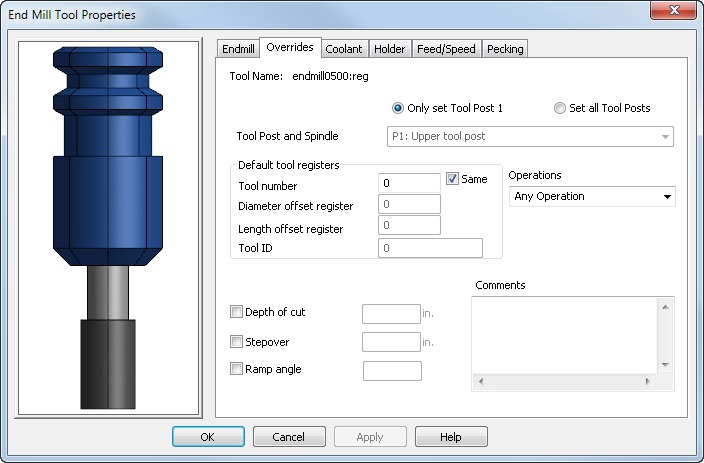

Use the Overrides tab of the Milling Tool Properties dialog to set the tool number, cutter comp register, and offset register for the selected tool.

Click the tool preview image to pan and zoom it. The orientation of the preview is determined by the settings on the Options > View > Machine page. Right-click the image to access a context menu.

Name — Specifies the name of the current tool.

Only set Tool Post 1 — Select this option to set the tool registers for only one tool post.

Set all Tool Posts — Select this option to set the tool registers for each tool post of a multi tool post machine. Select an entry in the Tool Post and Spindle list to choose the tool post you want to work with.

Default tool registers — Specify the register settings for the tool:

- Tool number — Specifies the slot number for the tool. Enter 0 to allow FeatureCAM to assign a value when the tool is used.

- Same — Select this check box to use the Tool number value for all the registers. Deselect the check box to set the registers individually.

- Diameter offset register — Specifies the diameter cutter compensation offset register number for the tool. This value is passed to XBUILD as <COMP-NUM>.

- Length offset register — Specifies the tool length offset register number. Most lathe controllers have a single register that contains the length and diameter offset values. In this case, the Length offset register is the important field to set in FeatureCAM. This value is passed to XBUILD as <OFFSET#>.

- Tool ID — Specifies the identification number of the tool. This is used by Bridgeport lathes and some Cincinnati machines.

Operations — Select an entry in the list to specify the type of operation for which FeatureCAM can select this tool. You can override this setting by selecting the tool manually.

Cycle — Select the type of drilling cycle to be used with the tool.

Spotdrill — This enables the spotdrill operation for insert drill tools. This is useful for high-speed drilling.

Depth of cut — Select the check box and enter a value to specify a depth of cut (Z-step increment) override for the tool.

Stepover — Select the check box and enter a value to specify the stepover distance override for the tool.

Ramp Angle — Select the check box and enter an angle to specify a ramp angle override for the tool.

Comments — Enter any comments for the tool. The post can be configured to output these comments.