Acceptable model geometry

Autodesk Moldflow Adviser works best when the model geometry is, on average, thin walled and composed of flat surfaces.

As a general rule, avoid models that are dominated by solid cones, solid cylinders, etc. However, there is no need to modify a model that contains such features, as long as they are not the majority of the model.

Note: For the above reason, you should not model runner systems.

Autodesk Moldflow Adviser's standard calculations are at their most accurate if the cavity walls are thin. The exact definition of thickness depends on the size and shape of the model. The following general rule gives satisfactory results:

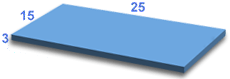

Consider the average of the length and width of a local region.

Average of 15 & 25 = 20 and Thickness (3) < 1/4 of average (5)

Ensure the thickness is less than one quarter of this average.

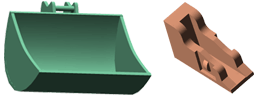

For real parts, it is time-consuming to apply the above rule to each wall. However, it is often possible to look at the entire part and decide whether or not it is suitable to be analyzed in the standard Autodesk Moldflow Adviser product. For example, in the following diagram it should be obvious that the model on the left has an acceptable wall thicknesses, but the model on the right has not.

If the part is not suitable for analysis in the standard Autodesk Moldflow Adviser product, an optional 3D Solver license can be purchased.