Auto-mesh analysis

You can now automatically mesh the model and launch the specified analysis at the same time. New meshing algorithms apply an appropriate global mesh density and also refine the mesh around small features.

Advantages

New Moldflow users can run an analysis without the need to first master meshing requirements.

Experienced users will appreciate the continuity of a large model being meshed and then having the analysis launched automatically.

Basic workflow

Import and prepare the model by specifying parameters such as material, injection location(s), analysis type, etc.

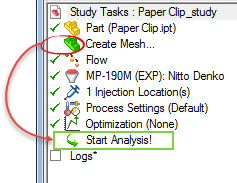

The following diagram shows that you can click Analyze without first meshing the model.

When you launch an analysis, the model is checked to determine if it has already been meshed. If not, two jobs are launched; one to mesh the model and the second to run the analysis.

You still have the option to mesh the part independently of an analysis.

This feature is supported for most of the conventional analysis sequences and for the following mesh type:

Midplane (except CAD body)

Midplane (except CAD body) Dual Domain

Dual Domain 3D

3D

Limitations

Analyses not supported:

- Cool (FEM)

- Core shift

- Thermoset Dispensing.

Boundary Conditions not supported:

- Prohibited gate locations

- Surface loads

- Dispensing controller

- Valve gates controllers.

Studies that mix CAD and Mesh are not supported. Example: CAD geometry + Part mesh.

3D runners are not supported, as you need to stitch them to the part after meshing.

The command runstudy does not incorporate the mesh feature.

The autosizing meshing parameter Scale Factor, does not apply.