Convergence errors most commonly occur during PRM generation and DED simulations, and are most likely due to the rate of energy input or the material properties being exceedingly non-linear.

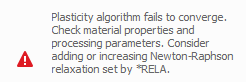

Plasticity Convergence Error

If the Plasticity algorithm fails to converge, the above error is issued. Common causes for this error along with possible solutions include:

- A large heat input combined with a small heat source - increase the size of the heat source. Doubling the heat source size has been shown to result is less that a 5% difference in distortion and stress results

- Custom plasticity properties are incorrect - plot the yield strength, ultimate tensile strength, and elongation vs temperature for the custom material along with the most similar of the property sets included with the software to check for typos or unit errors.

- Excessive non-linearties in the plasticity properties - if the properties are correct but unavoidably extremely non-linear, increase the numeric relaxation of the mechanical analysis.

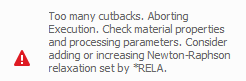

Too Many Cutbacks Error

When the solver fails to converge, it returns to the previous time step and attempts the solution again taking a smaller time step. This operation is referred to as a cutback. If too many cutbacks are taken it indicates the solver will not be able to converge a solution, and the simulation will stop, giving the above error message. The most likely causes for this are poor material properties, processing conditions, or mesh settings. Check that the model inputs are correct and re-run the simulation.

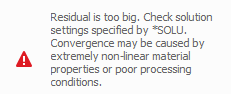

Maximum Residual Exceeded Error

If the residual during any increment exceeds the maximum residual, which is by default 1E20, the simulation will stop. This is typically due to severe non-linearties in the material properties, or due to excessively high energy inputs. Check these values and attempt the simulation again.