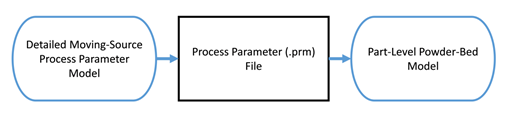

Netfabb Simulation Powder-Bed Part-Level analysis utilizes a two-part multi-scale modeling approach. This type of analysis can also be run with the Simulation Utility. A detailed Process Parameter model is linked to the Part-Level model through a Process Parameter (PRM) file. Figure 1 illustrates the workflow. The two stages of the analysis are described below.

Figure 1: Netfabb Simulation PRM file generation

Detailed process parameter model

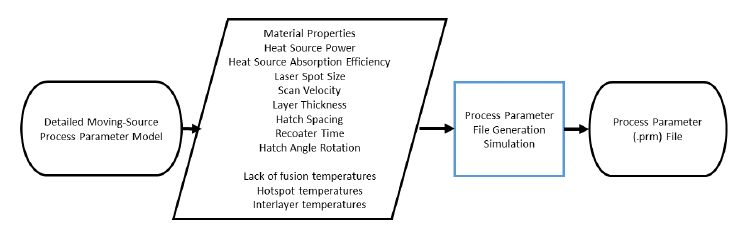

For each new set of process parameters, the user must generate a PRM file. The PRM file is an input into the part-level analysis that accounts for changes in the deposition settings. This type of analysis need only be run once for each set of parameters. Once the PRM file is generated for a set of parameters, it can repeatedly be used as an input into the part-level analysis. Figure 2 illustrates the workflow.

From version 2.91 onward, there are 3 kinds of PRM files that can be created:

- Mechanical analysis only

- Thermal analysis only

- Both mechanical and thermal analysis

Mechanical only PRM files are used to predict the part level distortion, residual stress, and stress relief heat treatment. Thermal analysis PRM files are used to predict lack of fusion or hotspots during laser powder bed fusion processes. Users can also opt to include both analysis types in a single PRM generation simulation. These PRM generation processes require the additional inputs of Lack of Fusion temperatures, Hotspot temperatures, and interlayer temperatures.

To obtain accurate PRM files, use prm_gen to produce the .prm file for each set of process parameters and material properties.

Figure 2: Netfabb Simulation Detailed Process Parameter Model

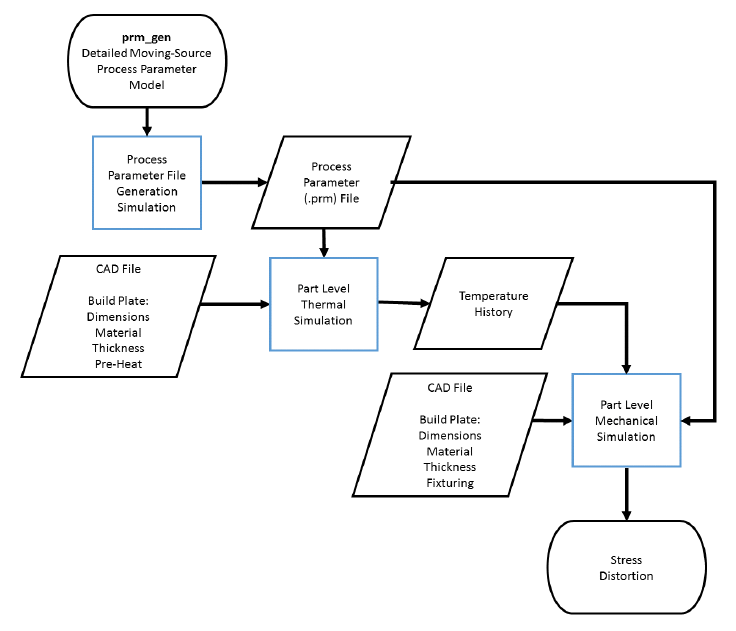

Mechanical only powder-bed part-level model

Description: The mechanical powder-bed part-level capability of Local Simulation allows for users to simulate the deposition of a component of any size or geometric complexity.

Output: The output of the mechanical analysis is interlayer temperatures, displacement, and stress. Post-process distortion and stress can be viewed both before and after support structure and removal from the build plate. Local Simulation can also predict support structure failure and part interference with the recoater blade due to excessive vertical distortion.

Common Uses: The results can be used to guide decisions about part orientation, support structure placement and design, distortion-based geometry compensation, and process planning.

Workflow: The approach begins by generating a process parameter (PRM) file based on known system parameters. The process parameter files for several materials using generic process parameter settings are included with the Netfabb Simulation license. Users should generate their own PRM files for the processing conditions and materials used in their powder bed systems. The process parameter file is input into the Netfabb Simulation thermal solver along with information about the geometry being built. The user can choose to simulate the entire build plate, or a simplified analysis of just an individual part. The output thermal history is then input in the Netfabb Simulation mechanical solver. Figure 3 illustrates the workflow for this analysis type.

Figure 3: Netfabb Simulation Mechanical Powder-Bed Part-Level Model

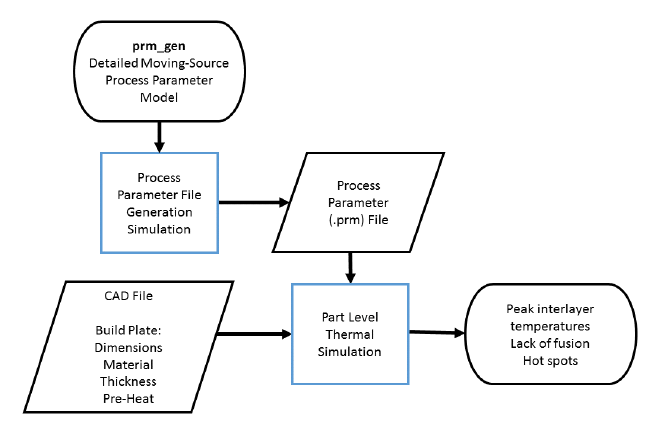

Thermal only powder-bed part-level model

Description: The thermal powder-bed part-level capability of Netfabb Simulation allows for users to simulate the deposition of a component of any size or geometric complexity.

Output: The output of the thermal analysis is peak interlayer temperatures, regions exhibiting lack of fusion or hot spots.

Common Uses: The results can be used investigate the potential quality of parts produced with a certain set of processing parameters using a particular material. This can prevent costly experimental iterations before printing with a new set of processing conditions.

Workflow: First a thermal PRM file must be created. Generic lack of fusion and hotspot PRM files are included with the solver, but users are advised to produce files based upon the processing parameters they use for their LPBF systems. Then a part scale thermal analysis is performed using the PRM file and the geometry or geometries of interest. The results show where regions where lack of fusion or hotspots may be an issue using the source processing parameters. The thermal only part scale analysis is shown in Figure 4.

Figure 4: Netfabb Simulation Thermal Powder-Bed Part-Level Model

Thermal and mechanical powder-bed part-level model

Users can produce PRM files with both thermal and mechanical information to drive part scale simulations. The process is identical to the sections above, where first a PRM generation process is completed, then that PRM is used with selected geometry or geometries. The results are predictions of lack of fusion, hotspots, distortion, and stress.