PowerInspect constructs a geometric item using the characteristics of the feature and the normals of the probed points.

Because PowerInspect automatically compensates for the distance between the probe surface and probe centre, each measurement can represent two possible contact points.

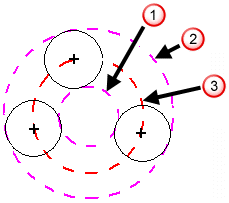

This example shows how PowerInspect can fit a circle through three probed points, which measure a circle in the part:

Internal circle

Internal circle

External circle

External circle

Circle fitted through probe centres

Circle fitted through probe centres

Depending on the direction from which the points were probed, PowerInspect compensates for the probe radius by projecting the probe centres to form the external circle or the internal circle.

Because the constructed circle depends on the normal of the probed point, it is important to trigger the probe as close to perpendicular to the surface as possible. The normal of the surface is then projected along the direction of the probe.

If you are using a fixed or touch trigger probe, the normal is in the direction of the probe deflection.