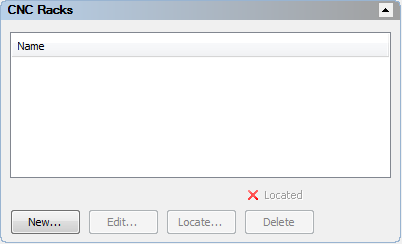

Specify and manage the racks you want to use during a CNC inspection.

A rack is a unit mounted onto a measuring device that contains multiple ports for storing probe-tool sub-assemblies.

Note: If you want to create a sub-assembly that can be stored in a rack, you must create it using a TP20 module connected to any compatible extension-stylus combination.

To specify a rack

- Connect to the measuring device using a CNC-enabled machine protocol or the I++ ClientTool protocol. The CNC Racks area is displayed in the

Machine tab.

- Mount the rack onto the measuring device and align it with a major axis.

- In the

CNC racks area of the

Machine tab, click

New.

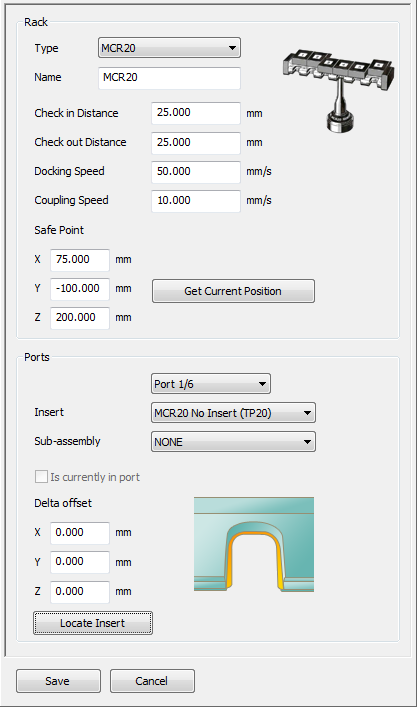

- In the Rack area, select the Type of rack in which you want to store the sub-assemblies.

- Enter a Name for the rack.

- In the

Check in distance box, enter the distance between the port's docking point and its check-in safe point

.

.

- In the

Check out distance box, enter the distance between the port's docking point and its check-out safe point

.

.

- In the

Docking speed box, enter the speed of the probe tool between the

Safe point

and a port's check-in and check-out safe points.

and a port's check-in and check-out safe points.

- In the Coupling speed box, enter the speed when connecting or disconnecting a sub-assembly.

To view or edit a rack

- In the CNC racks area of the Machine tab, double-click the rack in the list. The Rack dialog is displayed.

- Edit the rack, and then click Save to save your changes and close the dialog.

To delete a rack

- In the CNC racks area of the Machine tab, select the rack in the list.

- Click Delete to remove the rack.