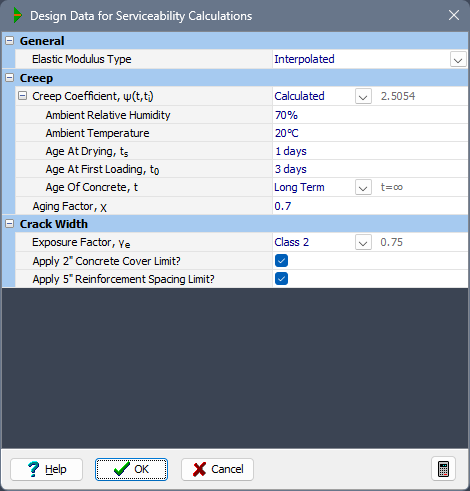

Service Limit State Calculations Parameters

Description

This form enables the parameters used in the Service Limit State stress and crack width calculations to be defined. Details of each parameter and the defaults supplied are contained in the help messages for the individual fields.

Form Graphic

Field Help

General

Elastic Modulus Type

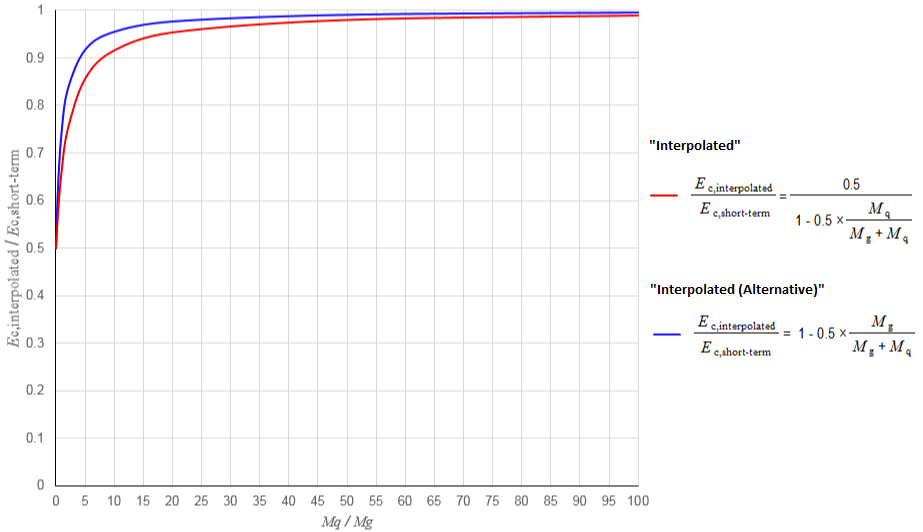

Article 5.7.1 of AASHTO LRFD details different modular ratio for permanent loads. This selection made here therefore allows for a value for modulus of elasticity between the short term and long term values, based on the proportion of permanent and transient loading. If 'Interpolated' is selected from this field, the program will derive a value from the following formula:

Es x El

E = —————————————————————

[El x R + Es x (1-R)]where:

El / Es = long term / short term E

R = ratio Mq/(Mg+Mq)

Mg / Mq = total moment permanent / live resolved perpendicular to neutral axis.

Axial loads are substituted for moments in the above formula if the ratio R above is greater for axial loads than it is for moments.

The above formula is derived as follows:

Total Stress Mq/z + Mg/z

E = ———————————— = —————————————————

Total Strain Mq/z.Es + Mg/z.ElMultiply top and bottom by Es.El.z/(Mq+Mg) and substitute for R to give the formula above.

If 'Interpolated (Alternative)' is selected from this field, the application will derive a value as a combination of the short and long term E:

E = Es x R + El x (1-R)

where parameters are defined as above.

Comparing 'Interpolated' and 'Interpolated (Alternative)' methods assuming Es/El = 2

If the value calculated in the above manner is not deemed to be appropriate, select either short term or long term and ensure that the value you wish to use has been entered in the materials property data.

Creep (for AASHTO LRFD 9+)

Creep Coefficient, ψ(t,ti)

When set to Calculated, the value for the creep coefficient ψ(t,ti) is calculated by the application following the methods of AASHTO LRFD 9 Article 5.6.1 and 5.4.2.3.2. The time dependant properties of the concrete are affected by the ambient relative humidity and temperature, as well as the age of the concrete. The default value is based on 30yrs concrete age, first loading at day 3, 80% relative humidity and the largest concrete compressive strength found in the cross section.

Alternatively, when set to User Defined, a value may be entered in the adjacent field. A value of between 1.0 and 2.0 is typical, depending on the concrete properties.

Ambient Relative Humidity

The average annual ambient relative humidity entered here is used in the evaluation of creep and shrinkage in AASHTO LRFD 9 Article 5.4.2.3.2-3 and 5.4.2.3.3-2.

Ambient Temperature

Age At Drying, ts

Age At First Loading t0

Age at Concrete, t

Aging Factor, χ

This is the aging factor used in the calculation of age-adjusted effective elastic modulus.

The default value is taken as 0.7 (for loads applied at a relatively young concrete age) in accordance with Article 8.13.1.3 of PCI Bridge Design Manual 4th Edition.

Crack Width

Exposure Factor, γe

This is the exposure factor used in "Control of Cracking by Distribution of Reinforcement" calculations.

The default value is taken as 1.0 for Class 1 exposure condition and 0.75 for Class 2 exposure condition, in accordance with Article 5.6.7 of AASHTO LRFD 9. Class 1 exposure could be thought of as an upper bound in regards to crack width for appearance and corrosion.

Set to User Defined to enter an alternative value.

Apply 2" Concrete Cover Limit?

If this checkbox is set, then the value of dc used in the "Control of Cracking by Distribution of Reinforcement" calculations is limited to 2" plus the bar radius, as detailed in Article 5.6.7 of AASHTO LRFD 9.

Apply 5" Reinforcement Spacing Limit?

If this checkbox is set, then the spacing value s used in the "Control of Cracking by Distribution of Reinforcement" calculations will not be less than 5", as detailed in Article 5.6.7 of AASHTO LRFD 9.