|

Adds corner seams to sheet metal faces. You can create seams between faces that are intersecting or coplanar. |

|

Access: |

Ribbon:

Sheet Metal tab

Modify panel

Modify panel

Corner Seam

Corner Seam

|

Shape

Controls the shape, gap measurement method, overlap type, and gap parameters for the corner seam.

|

Shape |

Selects model edges and specifies whether to rip corners. |

|

Corner Seam Specifies new corner geometry between existing coplanar or intersecting sheet metal faces. |

|

|

Corner Rip Specifies a ripped corner. Use this option to open a square corner to create a sheet metal corner seam (typically on a converted part model). |

|

|

Edges Selects a model edge on each face. |

|

|

Miter/Seam |

This area of the tab is labeled Miter when the edges selected are on coplanar face and labeled Seam when the edges selected are on nonplanar faces. The controls include:

|

|

Maximum Gap Distance - Use this option to create a corner seam gap that can be measured in a manner consistent with the use of a physical inspection gage. |

|

|

Face/Edge Distance - Use this option to create a corner seam gap that can be measured from the face adjacent to the first edge selected to the second selected edge. This option produces corner seams that are consistent with those produced by releases of Autodesk Inventor before R2008. |

|

|

Overlap Option: |

|

|

Note: The choices presented depend on the edges or faces selected, and the gap distance measurement method selected previously.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

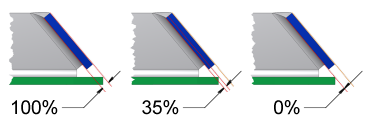

Percent Overlap Specifies the overlap as a percentage of the flange thickness using a decimal value ranging from 0 to 1. This option is valid when the overlap type is specified to be: overlap or reverse overlap. |

|

|

|

|

Gap Specifies the distance between the edges (or between a face and an edge) of the corner seam. Enter a value if it is different from the default Thickness value specified in the active Sheet Metal Style. You can also use the real value edit flyout on this field to: Measure a feature distance to use for this value, Show Dimensions to identify a dimension to use for this value, List Parameters that you would substitute for this value or reset the value to the Feature Value in the event that the value was previously changed. You can also specify Thickness to reset this value to the Thickness parameter defined in the sheet metal style in the event that the value was previously edited. NOTE If the overlap type for the corner seam has been set to No Seam this field is disabled. |

|

Bend tab

For information about the Bend tab, see Sheet metal bend options reference.

Corner tab

For information about the Corner tab, see Sheet metal corner options reference.

|

OK |

Click OK to create (or modify) a corner seam using the parameters and options specified and close the dialog box. |

|

Cancel |

Click Cancel to discard any edits made to parameters or options and close the dialog box. |

(More)

(More)

|

Extend Corner specifies how the corner is extended. |

|

|

Aligned |

Projects the first face so that it aligns with the second face. |

|

Perpendicular |

Projects the first face perpendicular to the second face. |