In this section, you create the patching and runoff surfaces for the mold assembly. Once created it is obvious that there are issues with creating the patching and runoff surfaces caused by the geometry in the model.

- On the ribbon, click Core/Cavity tab

Parting Design panel

Parting Design panel  Create Patching Surface

Create Patching Surface  .

. - On the Create Patching Surface dialog box, select Auto Detect

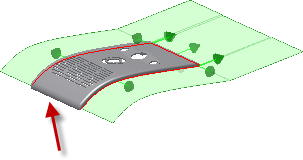

to create the internal patches automatically. The system detects as many internal patches as possible and lists them by name in the Creating Patching Surface dialog box. The patches are highlighted on the model in green. Rotate the model. Notice that the center section of the grill contains valid patches, but the two outer areas do not as shown in the following image.

to create the internal patches automatically. The system detects as many internal patches as possible and lists them by name in the Creating Patching Surface dialog box. The patches are highlighted on the model in green. Rotate the model. Notice that the center section of the grill contains valid patches, but the two outer areas do not as shown in the following image. Note: The missing surface patches can be created by deleting the bad patches on the grill and then using Click to add to select the edges manually. In the next section, you return to the part model and make an edit that allows automatic patching of all grill openings.

Note: The missing surface patches can be created by deleting the bad patches on the grill and then using Click to add to select the edges manually. In the next section, you return to the part model and make an edit that allows automatic patching of all grill openings. - Click Cancel on the Create Patching Surface dialog box to exit without creating the patching surfaces.

- On the ribbon, click Core/Cavity tab

Parting Design panel

Parting Design panel  Create Runoff Surface

Create Runoff Surface  .

. - On the Create Runoff Surface dialog box, select Auto Detect

to create the runoff surfaces automatically.

to create the runoff surfaces automatically. - The preview shows the runoff surface is not complete. Examine the preview and notice the change in curvature.

Note: The missing surface could be created manually by selecting edges. However, the runoff preview points out that a slight design change provides better parting results. In the next section, you return to the part model and make an edit to provide better parting results and automatic runoff surface generation.

Note: The missing surface could be created manually by selecting edges. However, the runoff preview points out that a slight design change provides better parting results. In the next section, you return to the part model and make an edit to provide better parting results and automatic runoff surface generation. - Click Cancel on the Create Runoff Surface dialog box to exit without creating the runoff surfaces.

- Click Finish Core/Cavity and save the assembly.