In this section, you use the runner sketch that you created in the previous section to create a runner.

The first step in creating a feeding system for the plastic melt is to create the runner system. Runners are channels for the plastic melt to flow from the sprue to the feed gates. The runner system consists of a main or primary runner, and possibly secondary or tertiary branch runners. A sprue feeds plastic melt to the runner system from the injection press.

A secondary sprue, or sprue runner, can also be added if you are working in a three-plate mold. This tutorial uses a two-plate mold.

- On the ribbon, click Mold Layout tab > Runners and Channels panel > Runner

.

. - From the Section Type list, select Semicircle.

- For the size of the semicircle, enter 3 mm.

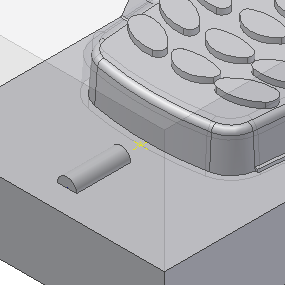

- Select the sketched line of the runner that you created in the previous step as the path for the runner. The runner is previewed in the model, as shown in the following image. Note: The runner is previewed with a cold slug. The default Cold Slug Position is based on the position that you selected on the runner sketch when you specified the path.

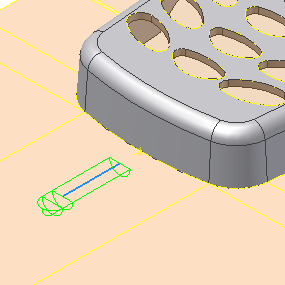

- Click in the Cold Slug Position cell of the Runner Segment table, and select None from the list. The runner appears as shown in the following image.

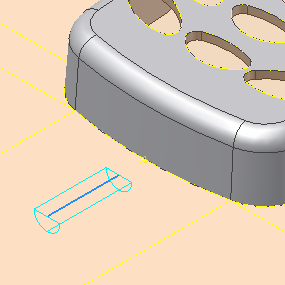

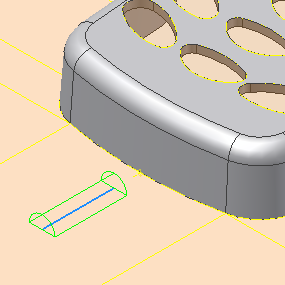

- When you create a semicircular runner, the runner can be previewed as part of the core or part of the cavity. To switch between both previews, select the Core Side and Cavity Side options in the Section Type area of the dialog. Switch the runner to Cavity Side. The preview updates as shown in the following image.

- Click OK to close the Create Runner dialog box.