View the results of the Fill+Pack analysis, and use the Results Adviser to provide specific information about the results.

The Study Tasks pane displays a list of the results that are available as a result of the Fill+Pack analysis you ran.

Look at the following results.

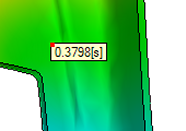

| Fill time | The Fill time result shows the flow path of the plastic through the model. A short shot will display as translucent. |

| Plastic Flow | The Plastic flow result is an alternative representation of the Fill time result. |

| Confidence of fill | The Confidence of fill result displays the probability of a region within the cavity filling with plastic. |

| Quality prediction | The Quality prediction result measures the expected quality of the model's appearance and its mechanical properties. |

| Pressure at end of fill | The Pressure at end of fill result shows the pressure distribution through the whole part at the end of fill. |

| Pressure drop | The Pressure Drop result displays the drop in pressure from the injection location to the selected area, at the moment that area was filled. |

| Temperature at flow front | The Temperature at flow front result displays the material melt temperature at each area, at the time it was filled. |

| Orientation at skin | The Orientation at skin result provides an indication of how plastic molecules will be orientated on the surface of the part. |

| Air traps | The Air traps result shows the regions where two or more flow fronts converge and the last areas that are filled. The regions highlighted in the result are positions of possible air traps. Rotate the model to see all the air traps. Air traps appear as small purple regions on a Dual Domain model or a small green patch on a 3D model. |

| Weld lines | The Weld lines result are shown as lines at the location of weld and meld lines in the filled model. Weld lines are color-coded according to their severity (blue is most severe). Rotate the model to see all the weld lines. |

| Grow from | The Grow from result is used when there are multiple injection locations. It shows which injection location filled what part of the mold. Use the Grow from result when you must balance the flow. |

| Average temperature | The Average temperature result shows the average temperature of the temperature profile across the thickness of the part. |

| Time to reach ejection temperature | The Time to reach ejection temperature result shows the amount of time it takes the material in an area to reach the ejection temperature. In a Dual domain model, this result starts from the end of fill. In a 3D model, this result starts at the beginning of the molding cycle. |

| Frozen layer fraction at end of fill | The Frozen layer fraction at end of fill result shows the thickness of the frozen layer as a fraction of the part thickness. A higher value represents a thicker frozen layer. |

| Volumetric shrinkage at ejection | The Volumetric shrinkage at ejection result shows the decrease in local volume. This has occurred from when the part was ejected to when the part has cooled to the ambient temperature. |