Before modeling runner surfaces, it is important to understand how runner sections are used by the runner balance calculation.

Runner balancing ensures that all the cavities finish filling simultaneously. The aim of a runner balance analysis is to achieve the balanced filling of all cavities in the mold by using different runner diameters.

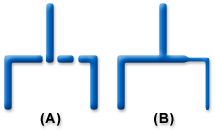

In the following diagram, (A) shows a runner system where the runner on the left has a single runner section, while the runner on the right has two sections. Diagram (B) shows how the Runner Balance tool might balance the system by assigning a single size to the left runner section, and assigning different sizes to the two sections in the right runner. This will result in a balanced runner system that has varying thicknesses in the secondary runners which may or may not be desirable depending on the mold requirements.

You can control the size increase or decrease of the runner dimensions by carefully considering the size of the runner surfaces.