Traditional ductwork is made of sheet metal which is installed first and then lagged with insulation as a second operation. Duct Board pre-insulated ductwork is installed in a single fix.

Duct Board patterns are made from rigid phenolic insulation panels with aluminium surfaces. A number of systems are available that utilise different cutting and marking techniques for creating Duct from this Material.

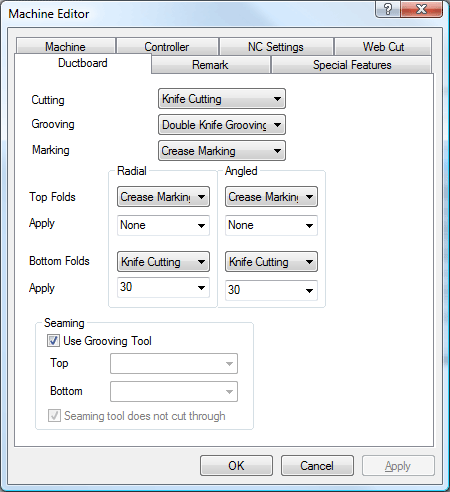

In order to satisfy the requirements of these Machines we have incorporated a Ductboard Tab in the Machine Editor Database.

The Duct Board Tab enables the user to customise settings to match the specific Tools and Settings on the required Machine.

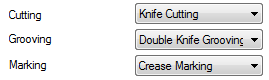

The first section determines the tooling and length of any Marking and Fold indicators. This is split into Tool Allocation where the user can define what tools will be used for Cutting, Grooving and Marking. The next section allows the user to define the tools to use for folding.

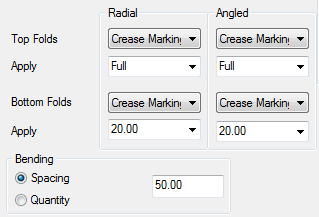

There are 2 types of fold, Radial (As used on a Radius Bend Back Wrapper) or Angled (as used on a Rectangular Bend Back Wrapper), and whether the fold is on the Top or Bottom of the material.

The Seaming Section allows the user to use the Default Grooving Tool to apply the Seam Chamfers or the user can specify what tool, from the available tools in installed machines, to use when Cutting or Marking Seam Edges.

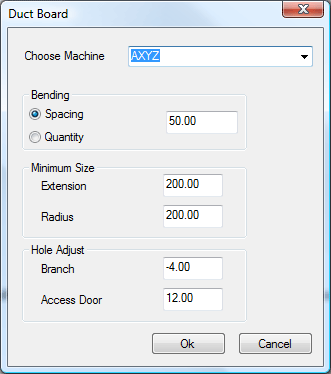

In addition to the settings in Installed Machines there is a seperate option in Pattern Database - Pattern Options where the user can specify if Spacing or Quantity is going to be used when marking Radial Folds (Bending).