Creates a shape between two sketched profiles.

- Access

-

Ribbon:

Sheet Metal tab

Create panel

Create panel

Lofted Flange

Lofted Flange

Shape tab

- Shape

-

- Profile 1

- Specifies the first profile sketch used to define Lofted Flange.

- Profile 2

- Specifies the second profile sketch used to define Lofted Flange.

- Flip Side

or

or

- Offsets the material thickness to the opposite side of the selected profile.

- Both Sides

- Offsets the material thickness equally to both sides of the selected profile.

- Profile 1

- Output

-

- Die Form

- Enables smooth, die formed output of the resulting Lofted Flange.

- Press Brake

- Enables faceted, press brake output of the resulting Lofted Flange

- Converge

- Specifies that bends of the flattened faceted sections converge near a point. Available only for Press Brake output type.

- Facet Control

- Specifies a method to control the size of the resulting faceted faces:

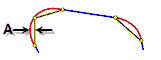

- A Chord Tolerance Input value determines the maximum distance from the arc segment to the face segment chord.

- B Facet Angle Input value determines the maximum angle to the chord segment at the facet face vertex.

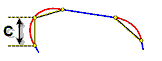

- C Facet Distance Input value determines the maximum width of the facet face (length of the chord) when subdividing the arc profile.

Option is available only for Press Brake output type.

- Control Value

- Specifies a value to control the facet type. Available only for Press Brake output type. Images display for facet types:

- Chord Tolerance

- Facet Angle

- Facet Distance

- Chord Tolerance

- Bend Radius

- Specifies a bend radius value that differs from the value in the active Sheet Metal Rule.

- Die Form

Unfold Options Tab

- Unfold Style

- Specifies a previously defined Unfold Rule that differs from the Unfold Rule in the active Sheet Metal Rule.