In a Dual Domain model, the thickness of the part is determined by calculating the distance between the elements on opposite sides of the part. Ideally, there would be a one-to-one correspondence between the elements, but in general this is not the case due to differences in the pattern of the mesh, or differences in geometry or curvature on either side of the part, etc.

Mesh matching is especially important for Dual Domain Fiber Warp analysis because inconsistent fiber orientation on both skins arising from mesh anomalies, rather than true flow behavior in the cavity, can adversely affect the warpage prediction.

- Match percentage

- The percentage of elements for which a matching element on the other side of the part was found.

- Reciprocal match percentage

- The percentage of the matched elements that match back to the same element.

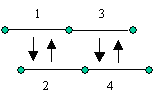

The following example illustrates perfect reciprocal mesh matching, where element 1 matches with element 2 and vice-versa, and element 3 matches with element 4 and vice-versa.

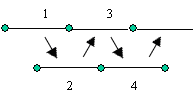

In the following example, the match percentage is 100% but the reciprocal match percentage is zero.

Recommended match percentage for analysis

The following recommendations apply:

- For general Fill+Pack analysis, the recommended minimum match percentage and reciprocal match percentage is 85%. If the match percentage is between 50 and 85%, a warning is given. If the match percentage is below 50%, the analysis will display an error and exit the analysis.

- For complex parts with a lot of ribs, higher match percentages are recommended.

- For Fiber Fill+Pack and Fiber Warp analyses, the recommended match percentage and reciprocal match percentage to achieve accurate results is 90% or higher. The minimum recommended match percentage for Warp analysis is 70% when using an unfilled material and 80% when using a fiber-filled material.