Inventor HSM provides several different feedrates that can be defined for each tool and the individual machining operations. Having all these feedrates available gives you added flexibility for reducing tool wear and machining time and increasing part quality. This list describes when the different feedrates are used:

Cutting feedrate

The primary feedrate used when machining. Colored blue in preview and simulation.

Lead-in (entry) feedrate

For milling strategies, this is the feedrate used when engaging the stock from a linking move. In drilling, this is used for the plunge and cutting movements. Colored green.

Lead-out (exit) feedrate

For milling strategies, this feedrate is used when leaving the stock for a linking move. Also colored green.

Ramp feedrate

The feedrate used when entering the stock with a ramp. Colored green. Ramping motion is used for the constant Z-level based machining strategies: Adaptive Clearing, Pocket, Horizontal Clearing, and Contour.

Plunge feedrate

Used for vertical movements entering the stock. These only occur if Plunge has been selected as the ramp type. Colored red. Plunge motion is used for the constant Z-level based machining strategies: Adaptive Clearing, Pocket, Horizontal Clearing, and Contour.

High feedrate

A yellow toolpath in preview and simulation indicate rapid movements and are output as G0, FMAX, or equivalent, depending on the post processor configuration.

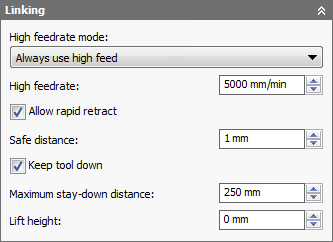

You may occasionally prefer to use high feed movements rather than rapid movements. In these cases, you can set the High Feedrate Mode on the Linking tab.

Changing rapid movements to high feed movements at 5000mm/min

Additional feedrates

For 2D Contour and Face, you can set a separate finishing feedrate which controls the feed for the last machining pass.

Adaptive Clearing allows you to set a feedrate for the non-engaging moves during stay-down linking.

Many strategies also provide a Feed Optimization feature that allows you to reduce the feedrate in the sharp corners.