Next we need to machine the central groove and to clean the corners/angles. This is because the previous operation left material in these areas due to the corner radius of the insert used. It is possible to do both tasks in a single operation using the Groove strategy to remove the excess material.

- On the ribbon, click

CAM tab

Turning panel

Turning panel

Groove

Groove

.

.

Tool tab

Tool tab

- On the Tool tab, click

to open the Tool Library.

to open the Tool Library. - Click the

button to add a new tool.

button to add a new tool. - On the Insert tab, select Grooving from the Type: drop-down menu. Then, select Square from the Shape: drop-down menu to specify the tool tip and enter the following values:

- Corner radius: 0.25 mm

- Groove width: 2.5 mm

- Width: 2.2 mm

Leave the rest of the values at their defaults.

- On the Holder tab, select External Grooving from the Style: drop-down menu.

- Change Head length to: 50 mm

- On the Setup tab, select Insert Center from the Compensation: drop-down menu.

- Click the

button to select the tool for your operation and close the tool dialog. This same tool will be used for a later parting operation.

button to select the tool for your operation and close the tool dialog. This same tool will be used for a later parting operation. - Click

to close the Tool Library dialog.

to close the Tool Library dialog.

Geometry tab

Geometry tab

Now remove the material the previous operation did not remove.

- Click the Geometry tab.

- Enable the Rest Machining group.

Passes tab

Passes tab

The parameters in the Passes group control how the grooving toolpath is calculated.

- Click the Passes tab.

- Enable the Finishing passes check box.

- Enable the Roughing Passes group.

Start the Calculation

- Click

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

at the bottom of the Operation dialog box, or right-click in the graphics window and select OK from the marking menu, to automatically start calculating the toolpath.

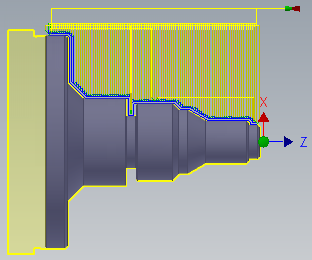

The toolpath is now calculated and a preview appears in the graphics window.

Continue to To Cut an External Thread...