Valve gates are used with a hot runner design in order to control how the cavity is filled, and to regulate the flow through each gate. As with all hot gates, valve gates are automatically trimmed.

The valve gate adds a valve rod to the hot runner gate. The valve gate can be activated to close the gate just before the material near the gate freezes. This allows for a larger gate diameter and smooths over the gate scar. Since the packing cycle is controlled by the valve rod, better control of the packing cycle is maintained, with more consistent quality.

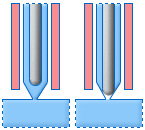

Valve gate systems are used to control various aspects of the part production, including how the cavity fills, part weight, cavity pressure, overpacking, weld lines, flashing and drooling. The gate shut-offs in valve gates are either tapered or cylindrical. Tapered shut-off pins are ground at an angle to match that of the gate orifice. Cylindrical, non-tapered valve pins seal around their perimeter using a tight tolerance slip fit in the cylindrical gate tip region. Both types work well with most resins, amorphous and semi-crystalline.