This example requires the Netfabb software in addition to Local Simulation. This example assumes a Windows installation of Local Simulation, however it can be completed by transferring files between the Windows machine where Netfabb is installed to the Linux machine where Local Simulation is installed.

All required input files listed in this example can be retrieved by executing the following command:

$ pan -t 09

After the above command is executed, a directory named 09 is created, containing all files.

Problem description

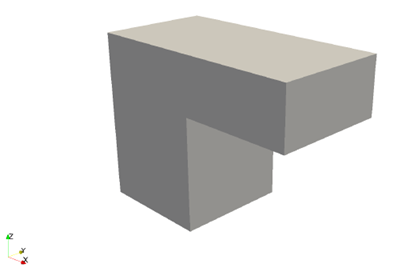

An Inconel overhang geometry with support structures is built in a powder bed system. The layer height is 0.04mm. The part geometry is imported in the analysis through an STL file, the support structure is imported from an CLI file, and both are automatically meshed within Local Simulation. The support structure for this build will be created by the user in this example. The build plate is modeled to be 12.7 mm thick using *DDM! and extended 10 mm in the 4 XY planar directions using *SBXY. The time to deposit layers is calculated using the *PBDL card. The bottom of the build plate is fixed using the *FSUB card. The *FSUB card will also simulate the release of the build plate from the machine after the deposition process is complete, but before the part is removed from the build plate. Support structure failure is modeled using the *UTSR card given a value of 1050 MPa. The part STL, is shown in Figure 9.1.

A time incremental thermal analysis is performed first to compute the temperature history of the part. Layers are activated in groups using *PBPA, and additional time increments are used to model heat conduction into the part. The thermal analysis includes only the part and substrate. Heat loss into the powder is modeled as convection with a value of 25.d-6 W/((mm2)–degC) using *CONV.

A time incremental mechanical analysis is performed after the thermal analysis is completed. Similarly to the thermal analysis, layers are activated in groups and the computed temperature distribution from the mechanical analysis is used to compute deformation due to the thermal expansion. These simulations have three additional post-process simulation increments, first Local Simulation simulates the release of the build plate from the machine, then the removal of the build from the build plate, and finally the removal of the support structure material from the final build.

Figure 9.1 Overhang STL