For several toolpaths, you can specify climb milling or conventional milling as the cut direction of the tool.

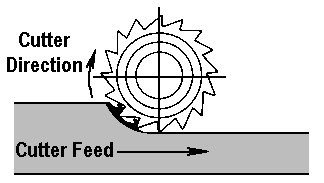

Climb milling

In climb milling, the teeth of the tool meet the block of material at the top of the cut, at the thickest part of the chip. This provides instant engagement of the tool with the block, providing a chip of definite thickness at the start of the cut. Climb milling does not cause the abrasive action caused by conventional milling. It also permits the gradual removal of the tool from the block, so that dwell marks are largely eliminated. Climb milling often provides a better finish, permits greater tool feed rates and prolongs the life of a tool.

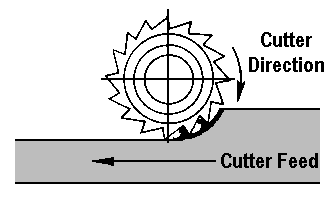

Conventional milling

In conventional milling, the teeth of the tool meet the block of material at the bottom of the cut. The teeth of the tool slide along until sufficient pressure builds up to break through the material surface. This sliding action, under pressure, tends to abrade the edge of the tool, which results in dulling. Also, the cutting action has a tendency to lift the block of material, fixture and table from their positions.