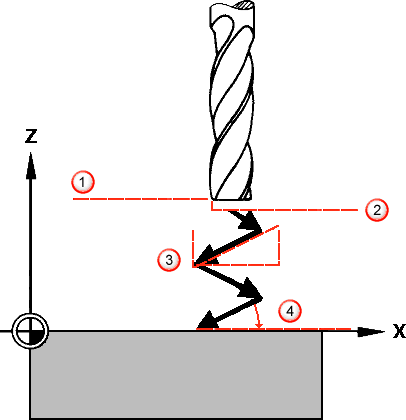

Feeding the cutter into the material surface in a straight plunge motion at full feed rate often causes pivoting around the tool in the direction of rotation. This, in turn, causes deflection. It is this deflection that causes gouging and, consequently, tool damage. Adding ramping moves allows the cutting tool to enter the block of material gradually, ensuring minimum tool damage and reducing the likelihood of gouging.

|

|

|

Safe Z

Safe Z

Ramp start height

Ramp start height

Ramp length

Ramp length

Ramp angle

Ramp angle