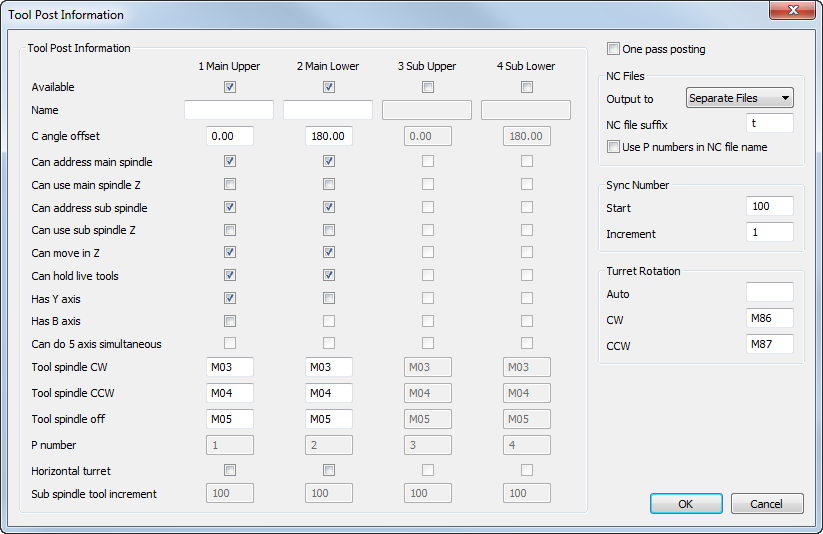

Select the CNC-Info > Tool Posts menu option to configure the tool posts. The Tool Post Information dialog is displayed.

Tool Post Information

FeatureCAM can support up to four tool posts:

- Main Upper — Main spindle side, upper tool post.

- Main Lower — Main spindle side, lower tool post.

- Sub Upper — Sub-spindle side, upper tool post.

- Sub Lower — Sub-spindle side, lower tool post.

Available — Select which tool posts are used in the CNC file.

Name — Enter a name for each tool post. This name is used to identify the tool post in the FeatureCAM interface.

C angle offset — This indicates the C angle for the tool at its start position. Typically upper tool posts are at 0.00 degrees and lower tool posts are at 180.00 degrees.

Can address main spindle — Select this option if the tool post can cut on the main spindle.

Can address sub spindle — Select this option if the tool post can cut on the sub-spindle.

Can hold live tools — Select this option if the tool post can hold drills or mills that can spin.

Has Y axis — Select this option if the tool post supports the Y axis.

Has B axis — Select this option if the tool post can hold tools that can rotate around the Y axis.

Can do 5 axis simultaneous — Select this option if the tool post supports 5-axis simultaneous.

Tool spindle CW — Enter the code to turn the tool spindle on in the clockwise direction.

Tool spindle CCW — Enter the code to turn the tool spindle on in the counter-clockwise direction.

Tool spindle off — Enter the code to turn the tool spindle off.

P number — Enter the ID number for each tool post.

Horizontal turret — Some Mazak Integrex two-turret machines have a horizontal lower turret. Select Horizontal turret to set the turret as horizontal. The same tools can be used to cut features on the main spindle and sub-spindle. FeatureCAM offsets the tool number, for example from T001 to T101, to tell the machine to rotate the turret to use the same tool on the sub spindle.

Sub spindle tool increment — This is the number by which FeatureCAM offsets the tool number to rotate a horizontal tool post.

One pass posting — Deselect this option to use multi-pass posting, where all operations on a tool post are posted in order before moving to the next tool post. Select this option to use one-pass posting, where all operations on all tool posts up to the next sync point are posted. While the operations are still posted in the order they occur, it is not guaranteed which tool post will be posted first.

NC Files

Output to — Specify how the NC code is saved:

- Separate Files — Output the NC code to separate files for each tool post (use this for Fanuc-style multi-turret lathes that require a separate program file for each turret).

- Combined Files — Output the NC code from all tool posts to a single file (use this for Okuma-style multi-turret lathes that require one program file for all turrets).

NC file suffix — When you save the NC code to separate files, the filenames consist of the name of the document, the tool post identifier, and the file extension specified in the General Information dialog. Enter a character in this box to specify the prefix for the tool post identifier. For example, enter P, and the saved NC files are saved as DocumentName.TXT, DocumentName.P2.TXT, DocumentName3.P3.TXT, and DocumentName.P4.TXT.

Use P numbers in NC file name — Select this check box to use the specified P number of each tool post in thefile extension of the NC program file. Deselect the check box to use the default numbering system for the extensions.

When Use P numbers in NC file name is deselected, FeatureCAM uses the following system to identify the code files of different turrets:

No extension — Upper turret, main spindle side

T2 — Lower turret, main spindle side

T3 —Upper turret, sub-spindle side

T4 — Lower turret, sub-spindle side

Sync Number

Start — Specify the initial M code number reserved for synchronization codes (also called wait codes). Most machines reserve all M codes above a certain number for synchronization codes.

Increment — This is the increment between synchronization codes.

Turret Rotation

Auto — This automatically rotates the turret to the next tool in the shortest direction.

CW — This rotates the turret to the next tool in a clockwise direction.

CCW — This rotates the turret to the next tool in a counter-clockwise direction.