In this task you review the press force results of the compression molding process. For this exercise you evaluate if the process settings are adequate to obtain the part thickness within 3% of the design thickness which is the tolerance set for this part.

To review the Press force: XY plot

- Click

Press force:XY Plot in the Study Tasks list.

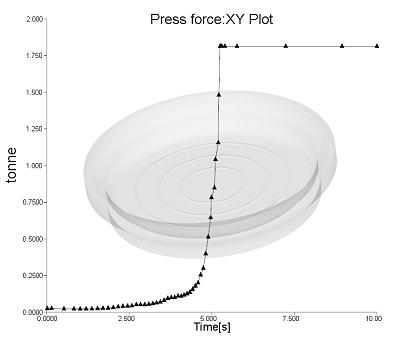

The Press force:XY Plot result shows the force applied by the press over the duration of the analysis, displayed on an XY plot of force versus process time. The maximum press force of about 1.8 tonne is reached shortly after 5 s which corresponds to when the press closes completely. Similarly to when the cavity volume stabilized seen in the previous result.

- Compare this plot with the process settings used for the analysis. The press force is calculated by multiplying the pressure by the projected area of the compression surfaces on the parting plane, at specific time instants.

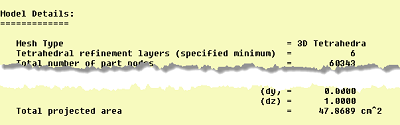

From the model details in the log file you have that the projected area is 47.8689 cm2.

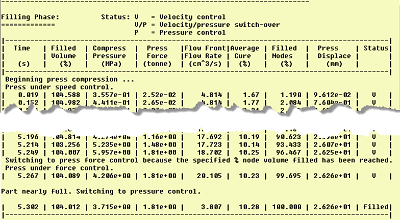

If you look at the log file filling phase you find the press pressure after the V/P switch over of 3.715 MPa.

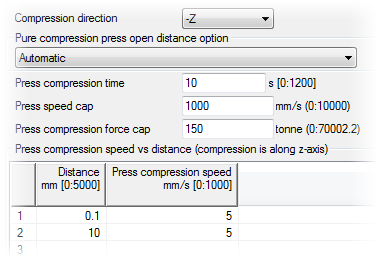

Multiply the pressure by the projected area and you have the press force of 1.81 tonnes which corresponds to the press force result. This value is well below the press compression force cap of 150 tonnes set in the analysis so the machine selected is within specifications.

Click the Next topic link below to move on to the next task of the tutorial.