This tutorial familiarizes you with the setup of the compression molding process and review of key results.

Tutorial duration: Approximately 45 minutes.

Autodesk Moldflow Insight is set for simulating injection molding of thermoplastics parts, by default. Most of the tasks required to simulate other processes are the same. However, the procedure to setup a compression molding process requires a few extra steps compared with the setup of an injection molded part.

In this tutorial, you will:

- Setup a compression molding analysis.

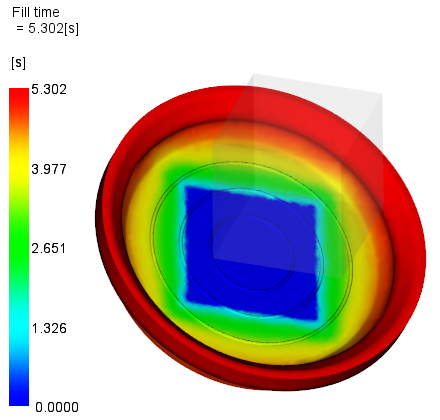

- Review key compression molding results.

Pre-requisites:

In order to complete this tutorial you need the following:

- License to run a compression molding analysis.

- Knowledge of the compression molding process.

- Knowledge of how to import assemblies and orient the parts correctly in the mold.

- Knowledge of how to create appropriate meshes, and if necessary, know how to fix potential mesh problems.

- Knowledge of the workflow and steps needed to setup and run an injection molding analysis.

Before you begin, click here to download the model files for the compression molding tutorial.

Tip: The list of tasks can be displayed at any time in the Help search panel. If this panel is not visible, click the

Show icon at the top of the help screen. Click the

Contents tab,

and the task required.