Pumps are installed in cooling circuits to provide the pressure necessary to compensate for frictional losses, minor losses and differences in elevation for dense fluids, when delivering a certain pressure at a desired point in the circuit. Most cooling circuits are driven by centrifugal pumps.

Centrifugal pumps consist of one or more rotating impellers contained in a casing. The centrifugal force of rotation generates the pressure in the liquid as it goes from the suction side to the discharge side of the pump. Centrifugal pumps have a wide range of operating flow rates with fairly good efficiency.

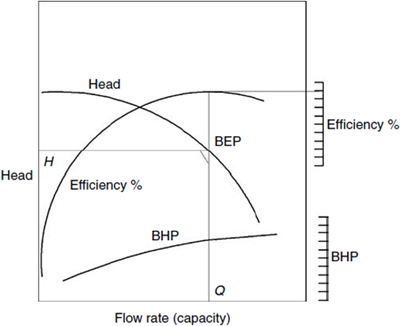

Since pumps are designed to produce a pressure at a given flow rate, the performance curve of a pump provides a very important characterization of that pump. The performance curve is a graphic representation of how the pressure generated by the pump varies with the flow rate. Other parameters such as the efficiency, nett positive suction head and horsepower are also presented graphically as part of the pump performance curves. The characteristic curve of a centrifugal pump depends upon the diameter of the pump impeller and the speed in revolutions per minute (RPM) at which the pump is operating. Pump manufacturers provide separate pump characteristic curves for each impeller size at each recommended RPM.

Figure 1. Generic performance curve for a centrifugal pump. (Image from Menon, E. Shashi. (2005), Piping calculations Manual, McGraw-Hill, Inc.)

The performance curves of a centrifugal pump consist of the head versus volumetric flow rate relationship, the efficiency versus volumetric flow rate relationship and the Brake Horse Power (BHP) versus volumetric flow rate relationship. The term Head is used in preference to pressure when dealing with centrifugal pumps. The units of Head are meters.

The head versus flow rate of the centrifugal pump characteristic curve in figure 1 shows that the higher delivery pressures are generated at the lower flow rates. In general the maximum head or pressure occurs at zero flow rate for pumps. This is known as the shut off head and the head decreases with an increase in flow rate.