In previous task, you reviewed the results of a Cool+Fill+Pack+Warp analysis.

There were two contributing factors to the warpage of the part, differential cooling and differential shrinkage. Both of these results indicate that adjusting the temperature should be incorporated in any solution.

- Open the

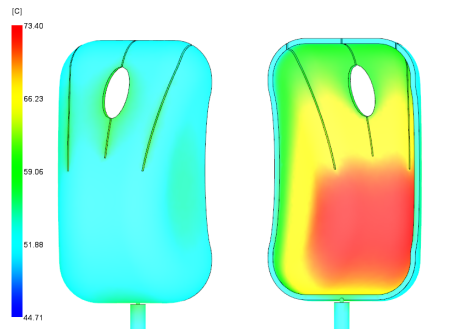

Temperature, mold-cavity interface (averaged) result.

Compare the core side and cavity side of the result.

The core side of the part is over 20C hotter than the cavity side

Fig 1:Temperature, mold-cavity interface (averaged) result.

The Cavity temperature is around 50C while the Core temperature is over 73C.

Another analysis was run with the core side coolant temperature reduced from 40C to 20C, the cavity side temperature was left at 40C. The results are outlined in Table 1

| Result | Core coolant temperature | Cavity coolant temperature | Value |

|---|---|---|---|

| Deflection, all effects: Deflection | 40 | 40 | 0.93mm |

| 20 | 40 | 0.62mm | |

| Deflection, differential cooling: Deflection | 40 | 40 | 0.83mm |

| 20 | 40 | 0.49mm | |

| Deflection, differential shrinkage: Deflection | 40 | 40 | 0.35mm |

| 20 | 40 | 0.34mm | |

| Temperature, mold-cavity interface (averaged)

(Core side temperature - Cavity side temperature) |

40 | 40 | 73C - 50C |

| 20 | 40 | 61C - 38C |

Table 1: Impact of reducing the coolant temperature on the Core side of the mold.

The overall deflection was reduced primarily as a result of differential cooling. The core side to cavity side temperature difference stayed at 23C.

Only reducing coolant temperatures may not solve the problem. The focused cooling of a baffle will address the core side hot spot. We have not addressed the differential shrinkage. Other factors such as melt temperature, packing profiles, and cycle time considerations need to be considered.

Be Adventurous

There may be multiple combinations that result in a successful injection molding setup. It is recommended that you:

- Save the study with a new name

- Alter a process parameter or cooling channel configuration

- Run another analysis

- Review the deflection results

Learn from both your successes and failures.