Transpose surfaces, and adjust the surrounding, or extend it with new triangles as needed, respecting normal angles

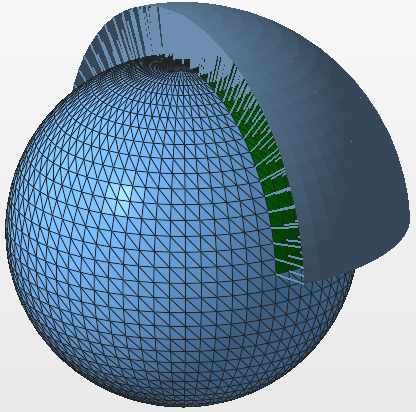

Extrude surfaces on the mesh to adjust the shape of the part in 3 dimensions.

- If not already opened, click to enter the repair module.

- Select the triangles or surfaces to be extruded.

- From the toolbar, click

Extrude Surfaces.

Tip: You can also access this command from the Mesh Edit menu or right-click the selection and choose

Extrude Surfaces.

Tip: You can also access this command from the Mesh Edit menu or right-click the selection and choose Extrude Surfaces.

Extrude Surfaces.

Initially, the surface is extruded a distance of 1 mm normal to the surface. The extruded surface is colored gray.

- In the context view, switch to 3D-Extrude.

- Click and drag the gray colored surface to adjust the extrusion height as necessary, or use the Shift slider.

- Enable one of the following extrusion types:

- Real Extrusion: Creates new triangles to create the extrusion.

- Move Points: Moves the points of the selected triangles, rather than creating new triangles.

- Thickening: Increases the thickness of the selected triangles.

Note: You should run the extended repair script after completing the thickening process to remove self-intersections and flipped triangles.

- Use the Optimization options as needed:

- Smooth considers the extrusion direction of the surrounding triangles. This helps to limit the contrast between the extruded surface and the adjacent surfaces.

- Improved takes the size of the selected triangles into account. The extrusion direction is determined primarily by the larger triangles.

- Click Apply to complete the extrusion.

Repair Part

Repair Part