Working environments preconfigured and set up for a variety of technologies and models of AM machines available on the market

Machine workspace focus print preparation work on particular additive manufacturing manufacturers and machine models. They include data such as build room size and material data, and may include further functions such as for creating support structures required or suitable for the particular manufacturing technology, or for packing and collision detection. The use of a machine workspace allows you to customize Netfabb specifically to the needs of your additive process and prepare your project for manufacturing with the constraints and possibilities that it brings.

Workspaces also provide access to simulation: Netfabb's simulation facilities are capable of simulating powderbed and DED processes. In the relevant workspaces you will therefore find an option to send parts and their supports, including the selected configuration, directly to simulation, saving you time you would otherwise have spent setting up the simulation parameters manually.

Main Workspace Types

Directed energy on powder layers

"Powder bed fusion", "Selective Laser Sintering", "Selective Laser Melting", "(Selective) Electron Beam Melting"

Metal powder, sometimes polymer powder, is deposited in layers onto a bed, and an energetic beam of light (eg. from a laser) or electrons is used to sinter or melt the powder where it hits, leaving a solidified spot of material. As the conversion is localized to a single point, toolpath generation is required to scan the desired cross-section area and contour lines to be rendered solid.

Directed energy, directed material stream

"Directed-Energy Deposition"

A stream of material powder is aimed at a weld puddle heated by an energetic beam of laser light or electrons. Requires toolpath generation.

Resin conversion

"Stereo Lithography", "Digital Light Processing®"

The process uses liquid photosensitive resins that are selectively activated and cured by light to form solid material. The conversion may be localized to a point if the light source is a narrow beam, requiring toolpath generation, or may happen for the whole layer at once if the light source is capable of projecting an image. The material conversion may happen at the air-resin boundary surface, and the part thus generated is lowered deeper into the resin vat as the solid layers build up, or it may happen by exposure through a window at the bottom of the vat, with the part being pulled upwards, away from the window, as the layers are rendered.

Extrusion

"Fused-Filament Fabrication"

A thermoplastic material is forced through a heated nozzle that is moved over a platform to deposit the material where it cools and solidifies. The process is repeated for every layer. Typically, the material comes as continuous filament, but granulate and other stock forms may be used, permitting composite materials that contain fibrous content to affect mechanical properties. The localized deposition requires the generation of a toolpath.

Multi-Gantry

"Collaborative Multi-Head 3D Printing"

This is a special workspace to provide and coordinate toolpathing for AM machines which have multiple printing heads that can be moved independently.

Manufacturer-Specific Workspaces

Example: HP Jet Fusion

The HP Jet Fusion printers fuses powder from layers using heat as well as liquid agents.

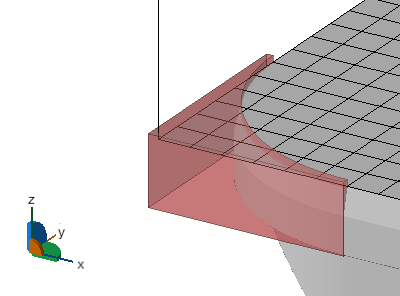

No-Build Zones

Some machines come with zones already defined where no building is allowed. If a part is placed in intersection with such a zone, you will be asked whether to proceed in your workflow. These zones are part of the machine workspace, defined by the machine manufacturer, and cannot be modified.

Example of a no-build zone as defined by the machine workspace

Flexible, configurable, and workflow-oriented access to machine workspaces

Flexible, configurable, and workflow-oriented access to machine workspaces