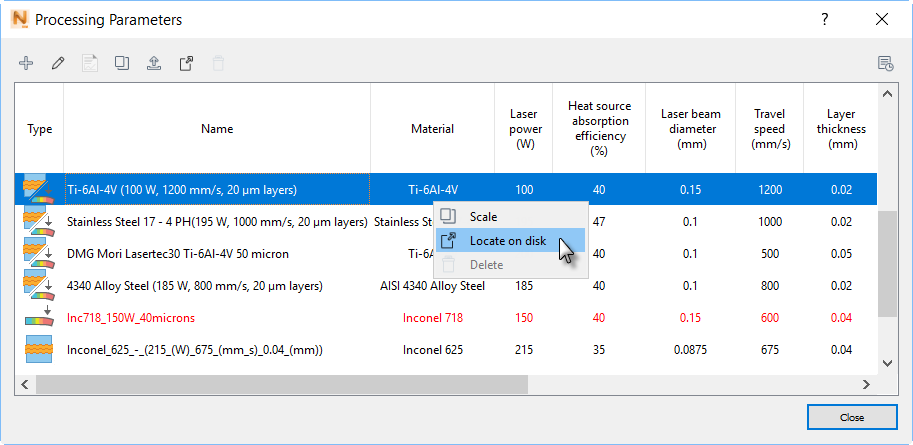

Processing parameter (PRM) files contain the thermal and mechanical response performed by a small moving source model for a specific set of processing parameters and a specific material. These files are the key component that drives part scale simulations. Upon installation, the processing parameters library includes some sample PRM files for common processing conditions and the materials included with Simulation Utility: AlSi10Mg, Cobalt Chrome, Inconel 625, Inconel 718, Inconel 718 Plus, Stainless Steel 17 -4 PH, Ti-6Al-4V, DMG Mori Lasertec30 Ti-6Al-4V 50 micron, and 4340 Alloy Steel. When a Simulation Utility project is saved, producing a TIVUS file, any associated PRM files, custom or generic, are saved in the project.

There are three types of PRM files, identified with different icons:

– for stress and distortion analysis

– for stress and distortion analysis

– for lack of fusion and hotspot analysis

– for lack of fusion and hotspot analysis

– for combination of stress, distortion, lack of fusion, and hotspot analysis

– for combination of stress, distortion, lack of fusion, and hotspot analysis

The Processing Parameters dialog allows you to manage the library of PRM files, using the right-click menu shown above, and the small icons across the top of the dialog. Left to right, the icons are used as follows:

– Create a new PRM file. Select this to create a new PRM file using custom parameters. Upon starting the PRM generation process, a PRM entry will be created in the Processing Parameters library. However the resulting PRM will not be available in the

Machine Dialog until the PRM generation has completed successfully.

– Create a new PRM file. Select this to create a new PRM file using custom parameters. Upon starting the PRM generation process, a PRM entry will be created in the Processing Parameters library. However the resulting PRM will not be available in the

Machine Dialog until the PRM generation has completed successfully.

– Edit the selected PRM file. This allows for the easy creation of new PRM files based upon existing or failed PRM simulations. Choosing Edit will import all the Process Parameters, Material Properties, and Simulation Settings from the original PRM creation.

– Edit the selected PRM file. This allows for the easy creation of new PRM files based upon existing or failed PRM simulations. Choosing Edit will import all the Process Parameters, Material Properties, and Simulation Settings from the original PRM creation.

– View the log file for a selected PRM file, if available. This command does not apply to generic, scaled, or imported PRM files.

– View the log file for a selected PRM file, if available. This command does not apply to generic, scaled, or imported PRM files.

– Create a new scaled PRM file, based on the selected PRM file.

– Create a new scaled PRM file, based on the selected PRM file.

– Import a PRM file into the library.

– Import a PRM file into the library.

– Open the directory that contains the selected PRM file; same as the menu option

Locate on disk.

– Open the directory that contains the selected PRM file; same as the menu option

Locate on disk.

– Delete the selected PRM file and associated files. The generic PRM files supplied with

Simulation Utility cannot be deleted.

– Delete the selected PRM file and associated files. The generic PRM files supplied with

Simulation Utility cannot be deleted.

– Open the

Job Manager. The Job Manager also provides an icon for opening the PRM log file.

– Open the

Job Manager. The Job Manager also provides an icon for opening the PRM log file.

A failed PRM file is shown in red text. This indicates that the system has found an error in the file properties. A user can investigate the situation by selecting the PRM file and clicking the Edit button along the top of the dialog.