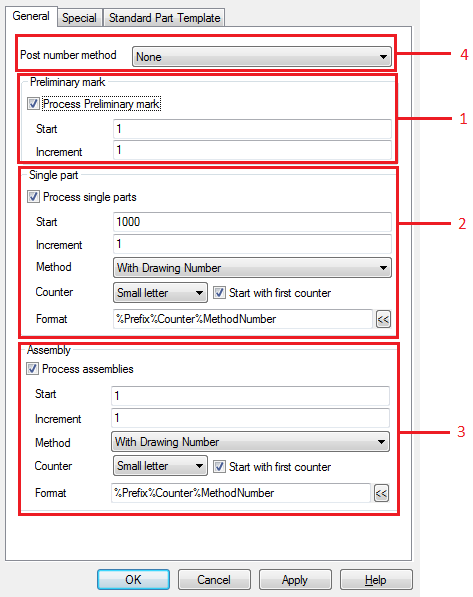

The main numbering dialog consists of four sections used to set up the numbering methods.

Some of the settings found in the Numbering dialog are stored in the default settings (Management Tools / Defaults category). Therefore, these settings can be applied for multiple users, shared through the AstorSettings/Default profiles and migrated to other versions.

Once a numbering method is set, click Apply to save it inside the project DWG file. The numbering method can be reused each time for the respective file, with the same settings (even if you send the file to a different computer that doesn't have the same settings as the initial one).

- Preliminary mark numbering method - This activates the preliminary mark numbering and allows you to set the start mark and the increment. This numbering method is independent of any post-numbering methods or Single Part / Assembly numbering, and can be performed at any point - especially in the preliminary stages of modelling, to allow the creation of raw material lists or general arrangement drawings

- Single part numbering method - This controls the method used to assign automatic numbers to individual part groups. It allows you to set the start mark, the increment and the display layout.

- Assembly numbering method - This controls the method used to assign automatic numbers to assembly groups. It allows you to set the start mark, the increment and the display layout.

- The post numbering method is applied once an initial method is used to assign part and assembly marks and it sets a set of predefined rules.

Single part / Assembly numbering methods

The methods for single parts and assemblies are identical in concept. A best practice recommendation is not to mix them in the setup and use the same method for both single part and assembly part marks. Mixing them is possible, but the results may not be as intended.

Advance Steel provides four different numbering methods:

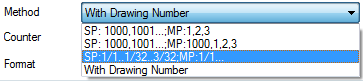

Method 1: SP: 1000,1001….;Mp:1,2,3

This is a standard numbering method where the part marks are given incrementally to groups, based on the start mark for each single part and assembly mark categories, using the independent increment for each category. This method doesn't add any relation between the elements or an external interference.

Method 2: SP: 1000,1001…..;Mp:1000,1,2,3

This method uses similar mechanisms as the one above, with single part and assembly groups being numbered independently, using the start and increment values, but it adds one particularity: standalone objects. The standalone objects are in the same time single part elements and an assembly (not being connected to anything else) and will get the same part mark for assembly as it was for single part.

Example: A standalone beam gets the mark "1005" based on the default numbering, the assembly mark will also be 1005 (ignoring the general assembly start and increment values). As a general best practice, those standalone elements will only get one shop drawing - an assembly drawing, so they will have a single part mark (referring to the single part numbering interval).

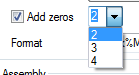

Add zeros option:

For both Method 1 and Method 2, an extra option appears in the dialog, called Add zeros:

When activated, this will add zeros in front of the part mark to reach a minimum size number.

Example: Selecting the value 2 for this option will output part marks that have only one decimal: 01,02, 03 and so on. Once the part mark reaches 09, it will continue with 10, 11 and so on, and, therefore, this option will no longer be applied. The option is also not applied if you set it to 4, and then set the start mark to 1000. The number already has 4 decimals, so the numbering will simply assign 1000,1001, ignoring this option.

Method 3: SP : 1/1….1/32…3/32;Mp:1/1…

This method ignores the start and increment values and assigns a simple numbering rule that starts with 1/1, goes on with an increment starting from 1 to 1/32, and then switches to 2/1……2/32….3/1 and so on.

Different prefixes assigned to the parts and assemblies will generate different multiple successions. Therefore, in a model you can have C1/1, B/1/, Ab1/1 and so on, where C, B and Ab are prefixes.

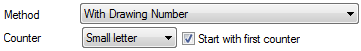

Method 4: With Drawing Number

A very commonly used method that allows Advance Steel to number the elements based on their position on the drawing, creating a strong relation between the element part mark and the drawing on which the object is detailed.

This method has the following workflow:

- You perform the numbering using the With Drawing Number method when the drawing is not yet numbered. The numbering will then perform the automatic identical part detection, grouping the identical parts and assemblies, and then assigning a placeholder mark to those groups of elements, generically called #internal1000, #internal1 and so on.

- The placeholder number is a valid number and Advance Steel can work with it very well, but its role will be highlighted in the next step.

- Create single part and assembly drawings: When a drawing is created, Advance Steel automatically assigns a drawing number which is unique per project. The start drawing number can be controlled, for example, during process detailing or individually, per object, if the detailing is performed manually, with drawing styles.

- Before replacing the #internal1000 placeholder part marks, Advance Steel also assigns a counter to the drawing number obtained from the detailing process. This counter is required to avoid duplicate drawing numbers if the detailing is performed with multi-sheet strategies.

The counter can be a letter (small or capital) or a number, and it represents the position of the drawing on the sheet. Therefore:

- It will always be 1, A or a for single-sheet drawings.

- It will always be 1, 2, 3 etc, for multi-sheets.

The Start with first counter option will reset the counter for each sheet. If left unchecked, the counter number will increase with each sheet, resulting in drawing numbers like: A100, B101, C102 and so on.

- The drawing number automatically assigned to the sheet is then used to replace the #internal1000 placeholder part mark. The process is done automatically during detailing, so once the drawings are created, the part marks are updated to match the new drawing numbers. See a more detailed example of the With Drawing Number method.

Change part marks using Change drawing number

As a common practice during a project, it is required to change the part mark of certain assemblies or part marks. Because using this method creates a link between the element mark and the drawing number where it is detailed, controlling the part will need an update of the two parameters, so the action in this case is to change the drawing number, which will trigger a change in the part mark.

- In the Output tab

Document Manager panel, click

Document Manager panel, click

(Document Manager).

(Document Manager).

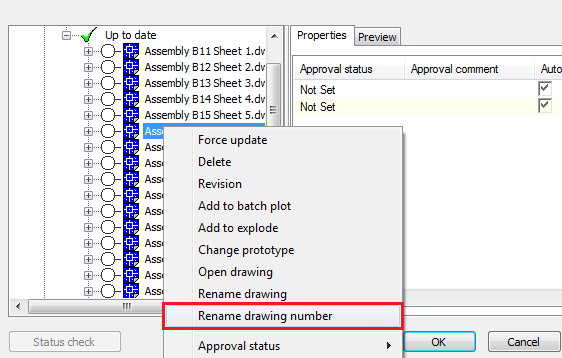

- Browse the drawing list and find the drawing where the object that needs a part mark change is detailed.

- Right-click on the drawing name and select Rename drawing number from the contextual menu.

- Enter the new drawing number. This functionality will:

- not allow you to insert a drawing number that already exists in the project.

- automatically change the part mark (single part or assembly) of the object(s) detailed on the drawing.

- change the file name and use the new drawing number value that is part of the filename.

- Once the drawing number is changed, this file and possibly other files will enter an Update required status, to perform a change in the label for the new part marks.

Single part / Assembly post-numbering methods

The post-numbering rules are applied after the initial numbering, changing certain part marks based on the rules to match the definition. They can be used to obtain the numbering as expected.

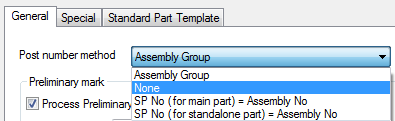

The post-numbering method is set from the combo box in the top of the Numbering dialog, and offers the following options:

- None

- SP Number (for main part) = Assembly Number

- SP Number (for standalone part) = Assembly Number

- Assembly Group

- None: no post-numbering method is applied. Part numbers and assemblies are numbered separately.

-

Assembly Group: this post-numbering method will change all the single part marks to match the assembly part marks, together with an identifier to generate a unique part mark.

Example:

A model has three different assemblies numbered: B100, B101 and B102.

- Assembly B100 has the attached parts: p1000, p1001

- Assembly B101 has the attached parts: p1000, p1002

- Assembly B102 has the attached parts: p1002, p1005

All those marks were a result of a standard numbering, without using any post-numbering methods.

- The model will still have the three assemblies: B100, B101 and B102, unmodified.

- The two attached parts from B100: p1000 and p1001 will change their single part marks to: pa-B100 and pb-B100, where:

- "p" is the prefix (p1000).

- "p" is the prefix (p1000).

- "a" and "b" are counter marks that trigger a difference between the two elements.

- "-B100" is the assembly mark to which those two plates belong.

- Going to assembly B101, the two attached parts that it previously had: p1000 and p1002 will change to: pa-100 and pa-B101. The reasons are:

- "p1000" that was also attached to this assembly will switch its mark to "pa-B100", because this attached plate already had a part mark from the previous assembly. As the element is still identical to the attached part from assembly B100, it will keep its name.

- "p1002" is a new part mark that didn't belong to the other assembly, so it will get a single part mark that contains the B101 assembly mark: pa-B101.

- For assembly B102, the two attached parts: p1002 and p1005 will change to pa-B101 and pa-B105, using the same logic as above.

The attached parts will take the assembly mark in an ascending number order and once set it is reused for all the other assemblies. If the attached parts would be different as single part marks between assemblies, then this rule would allow a very good grouping of part marks, where just checking the attached part mark would give direct information of which assembly it belongs to.

-

Sp No (for main part) = Assembly No: This method will assign to the element that represents the main part in the assembly the same single part mark as the assembly mark.

Example:

A column assembly C100 has, after numbering, the single part mark: c1000 for the column beam, and p1000 for the base plate. Applying this post-numbering method will change the single part mark for the column beam to C100, leaving the base plate as p1000.

This method is very useful if the numbering is done using the With Drawing Number method and the process is configured to not create single part drawings for the main element in the assembly. Due to this, the main element in the assembly (for example the column beam element) will not get a single part drawing to generate its single part mark, so it will remain as #internal.

- Sp No (for standalone part) = Assembly No: This method only applies to standalone elements (e.g. bolted purlins, claddings) and the method will simply set the same single part mark as the main part mark, regardless of the single part main numbering method.